|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – PDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

8

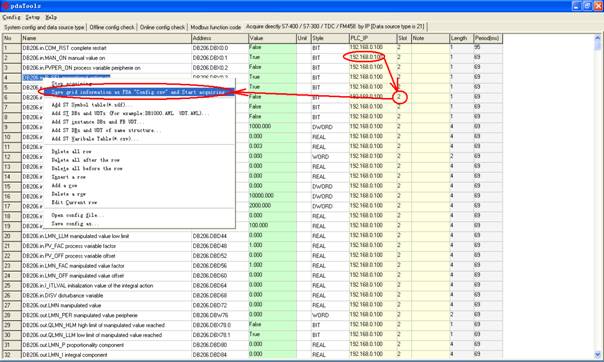

S7 PLC Tools for program debugging - pdaTools

The same technology is used as

the last section, the variable address can be imported to pdaTools in batches

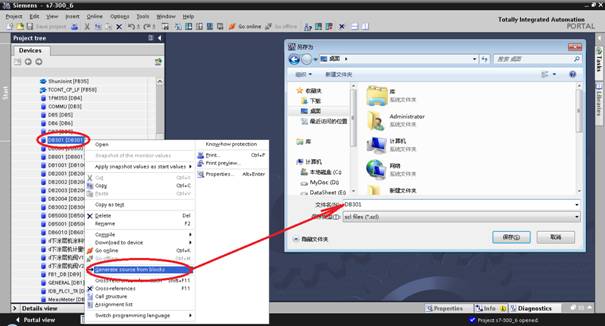

by derived from the Step 8.1

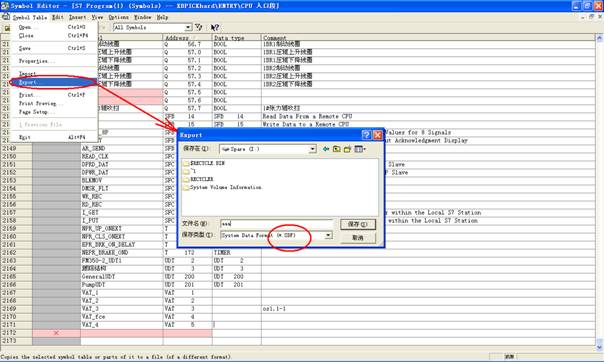

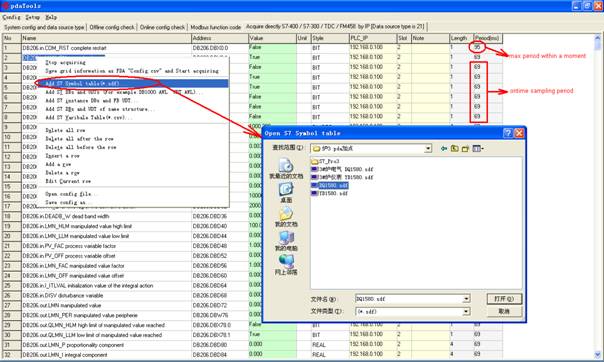

Online Step7 Symbol table and Measure sampling period

Export STEP7 symbol table as sdf file, for example I:\aaa.sdf.

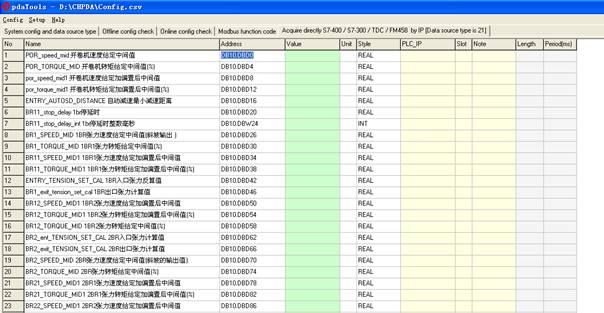

Run pdaTools.exe to open I:\aaa.sdf, fill in PLC’s IP and CPU’s slot, you may start requiring PLC ontime data, Variable information may be modified in grid, Sampling period is at column Period(ms). The first row is max period for some time, You may also save the multi-PLC config into PDAServer, it will collect PLC’s data together.

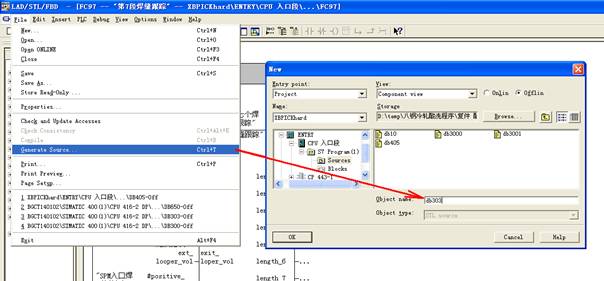

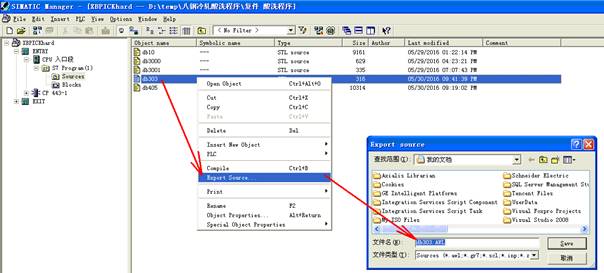

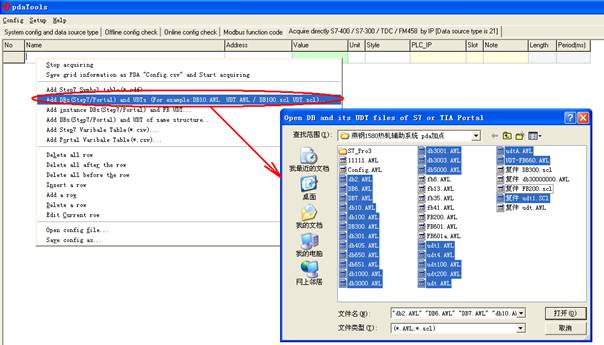

8.2 Online Step7/Portal multi-DB and Measure sampling periodGenerate source for STEP7 DB and export source as AWL file, DB number is file name, for example I:\DB303.AWL. Export a DB to a AWL file, all UDT to UDT.AWL.

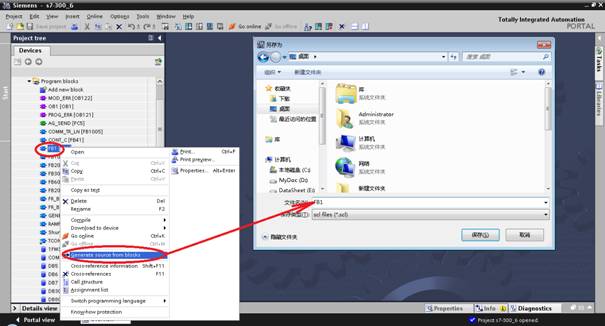

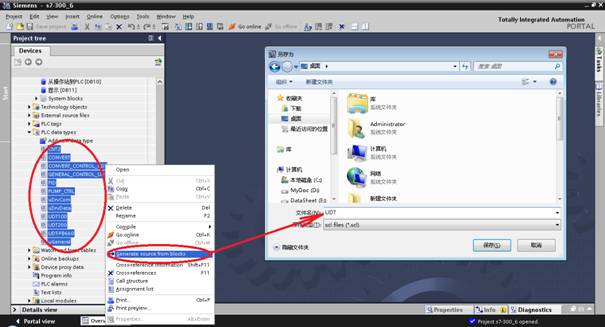

Generate source from blocks to .scl file for DB in Portal.

8.3

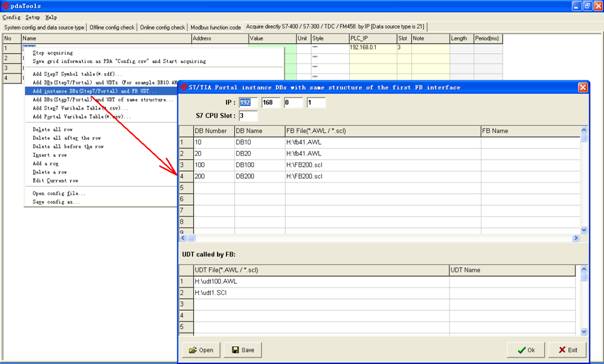

Online Step7/Portal instance DBs and Measure sampling period

To generate and export the source file for the user defined function block FB and UDT called to AWL file, Generate source from blocks to .scl file for FB and its UDT in Portal.

Instance DBs of FB may be collected if you follow below.

8.4

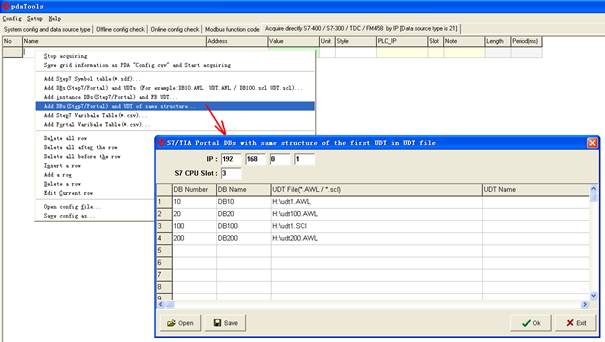

Online Step7/Portal DBs with same structure of UDT and Measure sampling

period

The source file cannot be generated for SIEMENS Step7 system function block SFB, you may define a UDT with the same variables interface. Generate source from blocks to .scl file for PLC data types in Portal.

Instance DBs of SFB may be collected if you export the UDT to AWL file and following below.

8.5

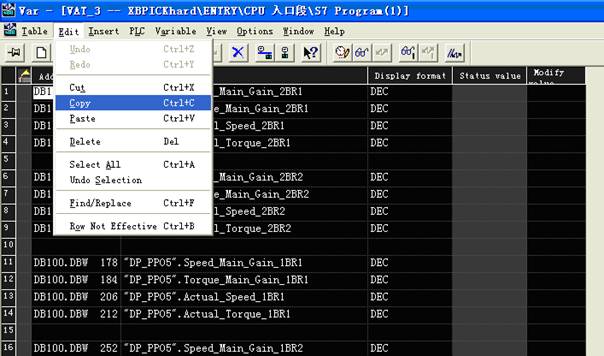

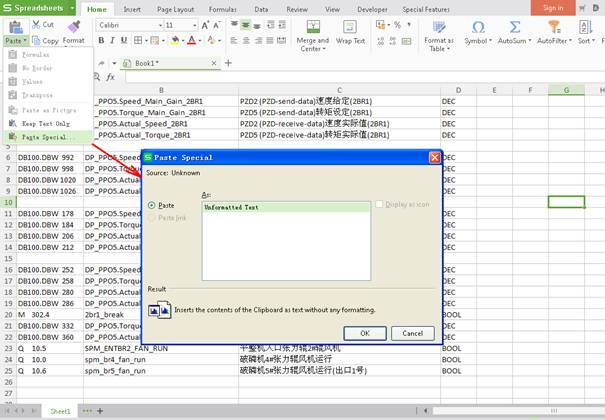

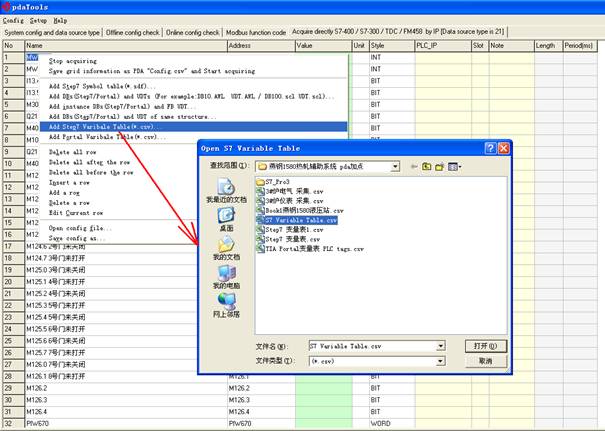

Online Step7 Variable Table and Measure sampling period

Copy STEP7 variable table and paste to Excel with text style, save as csv format file, for example I:\Book1.csv.

Run pdaTools.exe to open I:\Book1.csv, fill in PLC’s IP and CPU’s slot, you may start reading PLC ontime data, Variable information may be modified in grid, Sampling period is at column Period(ms). The first row is max period for some time, You may also save the config into PDAServer, it will collect PLC’s data together.

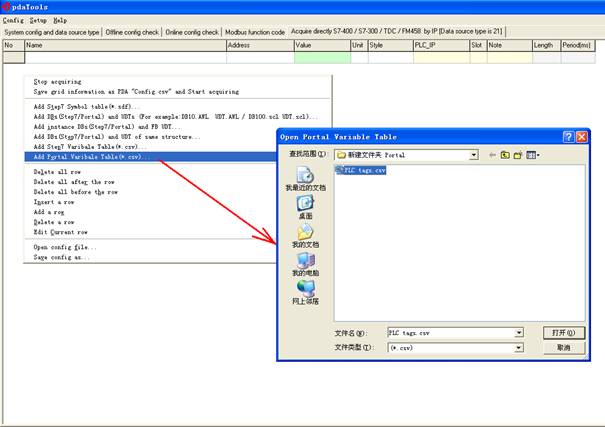

8.6 Online Portal Variable Table and Measure sampling periodExport Portal variable table as .xlsx file, save as .csv format file, for example I:\PLC tags.csv.

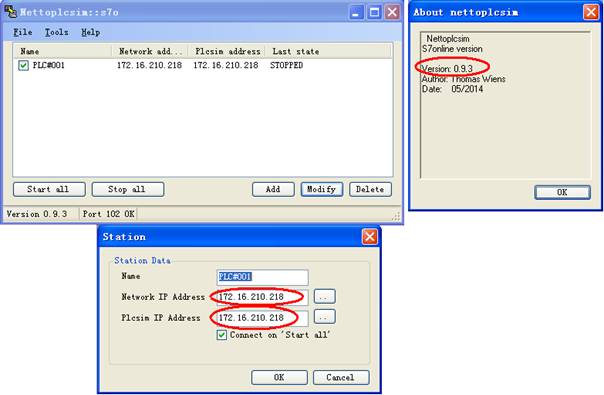

8.7 Requiring NetToPLCSim data(1) Setup is below for NetToPLCSim. SIMATIC S7DOS Help Service should be stopped.

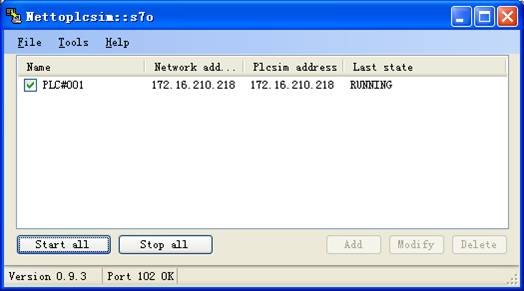

(2) It is below after "Start all".

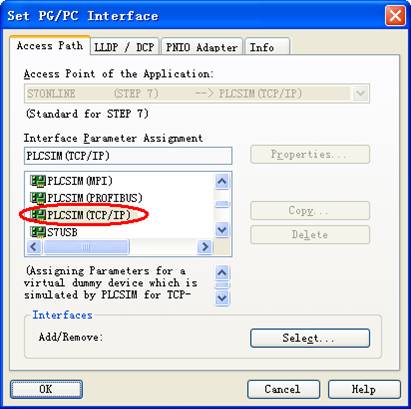

(3) Run Step7. (4) Set PC's IP as PLC ethernet IP and connect to switch, install S7-PLCSIM V5.4+SP3 or higher edition, Select PLCSIM(TCP/IP) for Set PG/PC Interface in Step7.

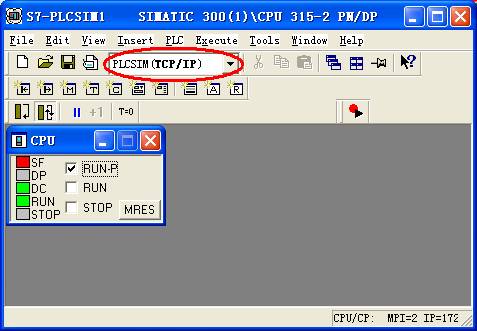

(5) Run PLCSIM, PLCSIM(TCP/IP) is selected for PLCSim.

(6) Download s7 program. (7) By Configuring the

collected signals on the PDA computer, they can be collected normally. |

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient