|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data Acquisition – CHPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

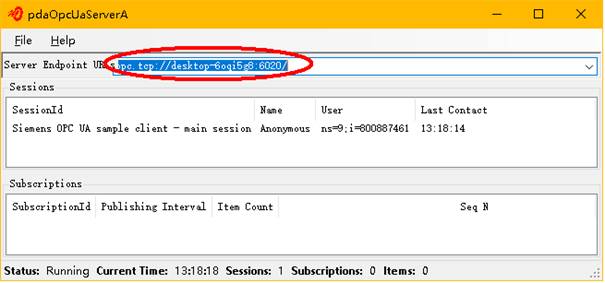

71 Opc Ua Interface pdaOpcUaServer

Note for each connection in PDA Config.csv cannot be repeated.

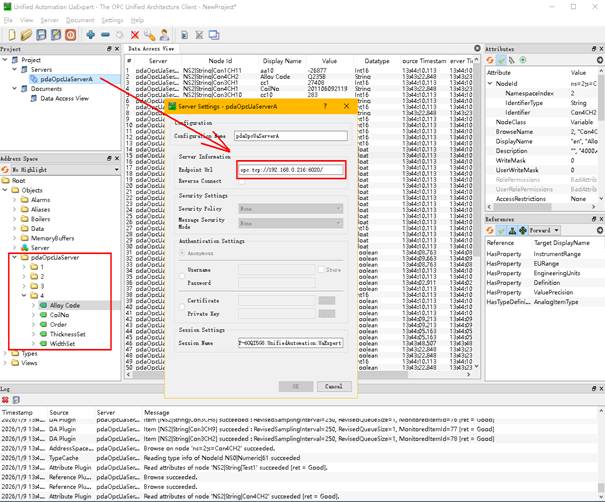

Extract PDAOpcUaServer. zip to the \ PDA \ directory, \ PDA \ PDAOpcUaServer \ PDAOpcUaServer A.exe reads real-time data from PDAServer and writes it to the node of Opc Ua. The Field column in Config. csv is BrowseName, the Name column is DisplayName, and the Id column is Description. Modify the file Quickstarts.ReferenceServer.Config.xml as follows, specifying the IP and port bound to PDAOpcUaServer, localhost can also be filled in to access data through any network card.

Delete all directories under C: \ ProgramData \ OPC Foundation \ pki \ own in order to regenerate the certificate automatically. 71.1

Install

Stop uninstalling all other Opc Ua Discovery Servers on the computer, involving directories such as c: windows system32, C: Program Files (x86) OPC Foundation, C: ProgramData OPC Foundation, etc. Otherwise, it may cause conflicts.

PDAWatchDog will automatically start PDAOpcUaServerA.exe, or you can manually run PDAOpcUaServerA.exe. The interface after startup is shown in the following figure.

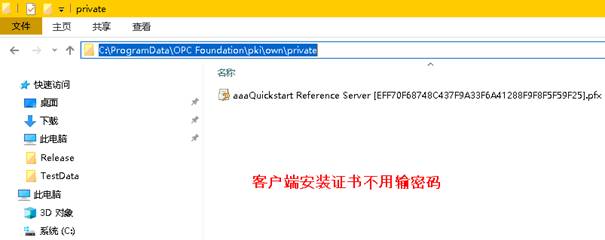

71.2 CertificateWhen pdaOpcUaServer starts, it will automatically generate a certificate, and the private key certificate is stored in C: ProgramData OPC Foundation pki own private, as shown in the following figure.

The pfx file needs to be sent to the Opc Ua client and installed. Double click on the certificate file under Windows to complete the certificate installation, as shown in the following figure.

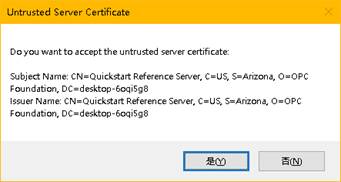

If you do not install a certificate or install a public certificate, the client will be prompted for an untrusted server certificate when connecting, as shown in the following figure. After "Y", data access will not be affected.

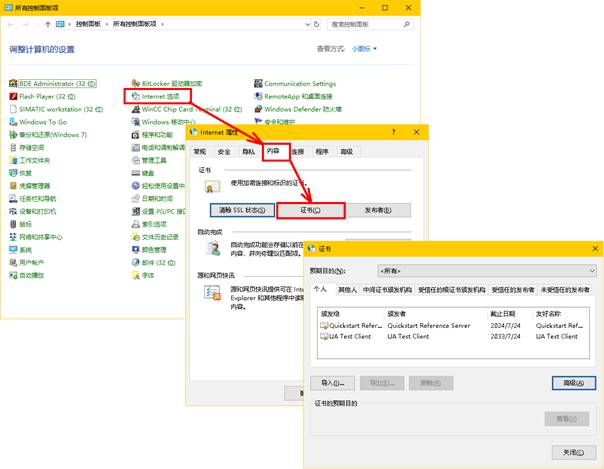

The operation interface for viewing, importing, exporting, and deleting certificates under Windows is shown in the following figure.

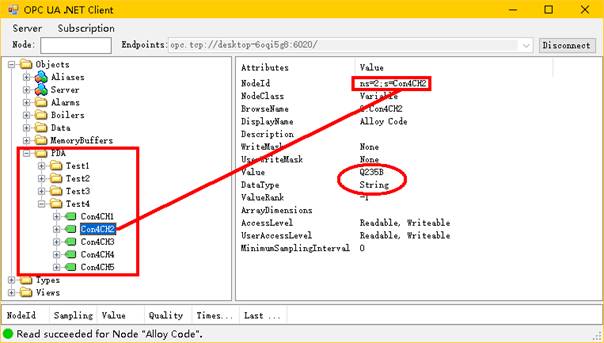

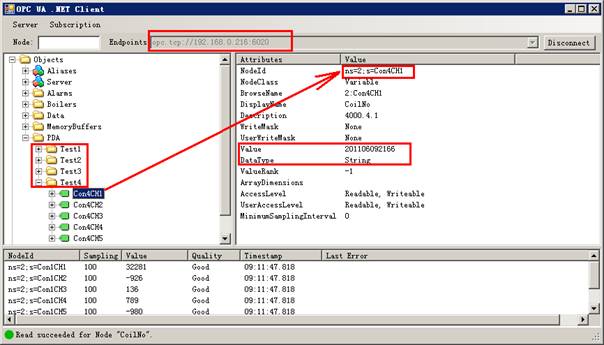

The node structure and real-time values accessed by Opc Ua client are shown in the following figure.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient