|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – ikoPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

29

Beckhoff Ethernet

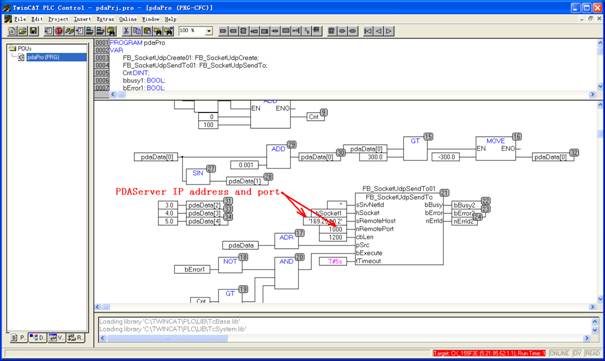

CPU with WinCE kernel should be selected, the valid sample period may be 0.25ms, it is more effective than WinXp or Win7 kernel. Please ask for the project example Beckhoff_pdaPrj.rar if needed, UDP is used, the data source type is 25, see section 4.3, Single PLC can send 1423Bytes/2ms once, PLC acquisition process is shown as below. it is triggered at rising edge, Program cycle is set to 1ms. Another PDAServer can read Beckhoff PLC variable name or memory address directly, no any acquisition process is required in PLC, the acquisition rate is 10ms or more.

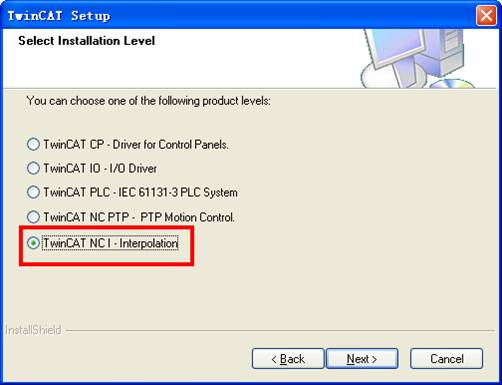

Exit 360 antivirus, 360 guards. The controller default IP network segment is: 169.254.xxx.xxx, subnet mask is 255.255.0.0, The computer should be set to the same mask, Otherwise, no PLC can be searched. Run \tcat_2110_2232.exe to setup Beckhoff program tool, it’s kernel is CoDeSys.

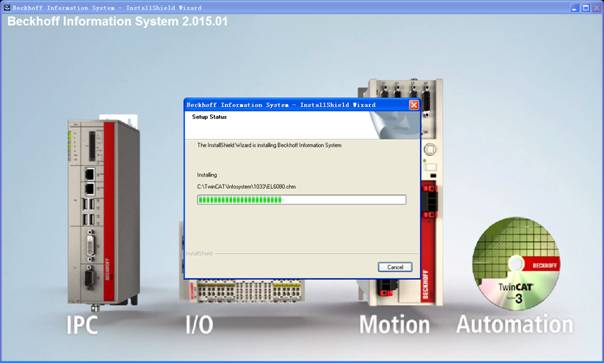

You need to reinstall if there is the serial number. Run InfoSys.exe to setup manual and help documentation.

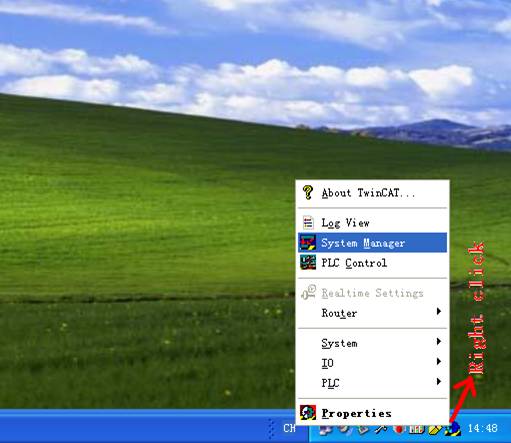

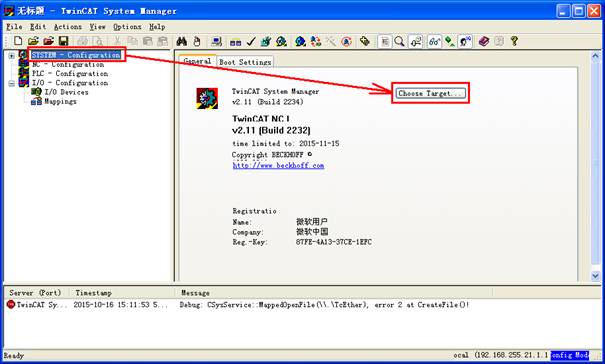

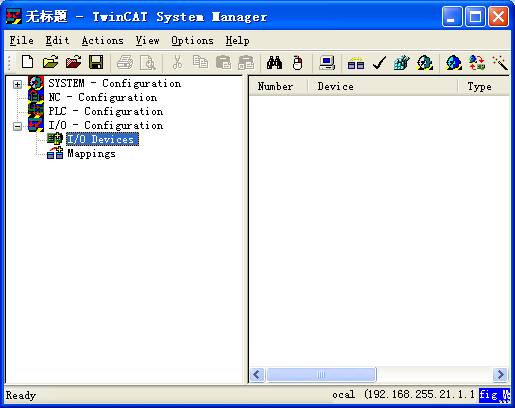

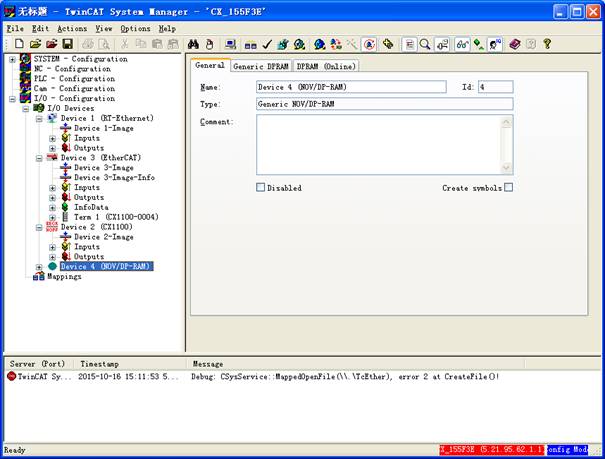

Set PC to the same network segment as PLC. Enter TWinCAT System Manager

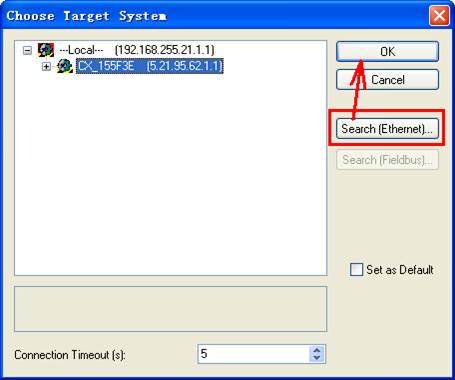

Select target PLC.

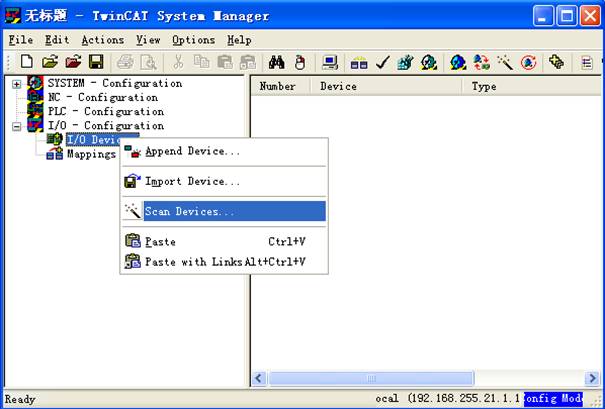

Search device on the ethernet.

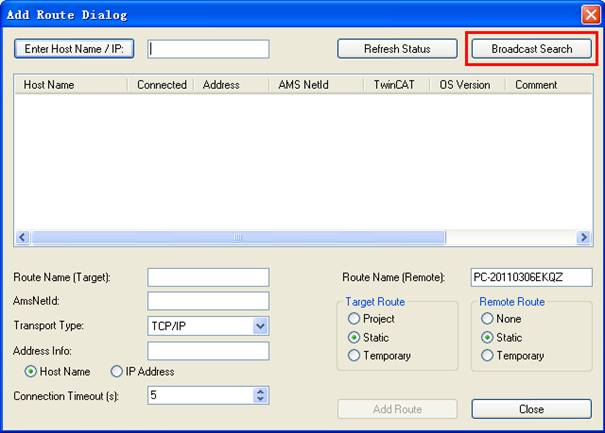

Broadcast search network to find device supported by BECKHOFF.

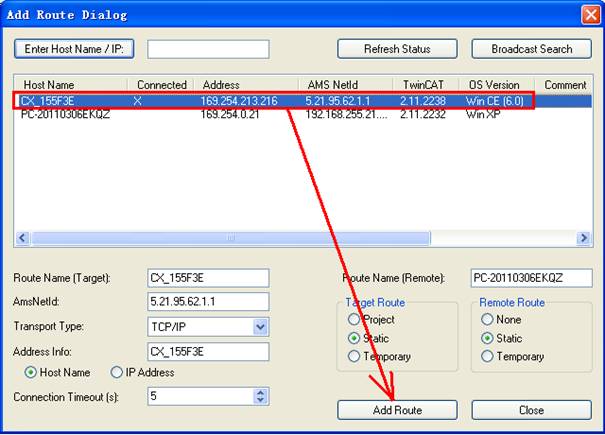

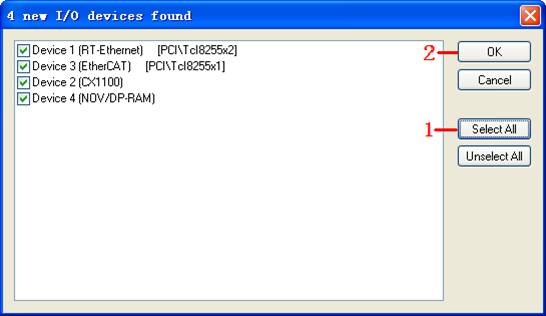

Select target PLC in the searching results.

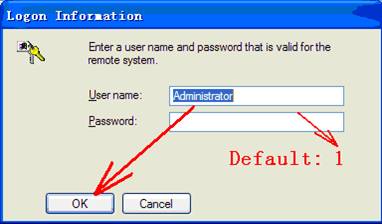

Input PC or PLC password, Do not input if no password.

Enter hardware configure.

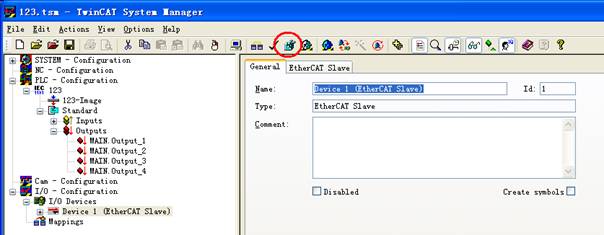

Scan devices.

Save result as Test.tsm, It will be automatically loaded when system manager startups.

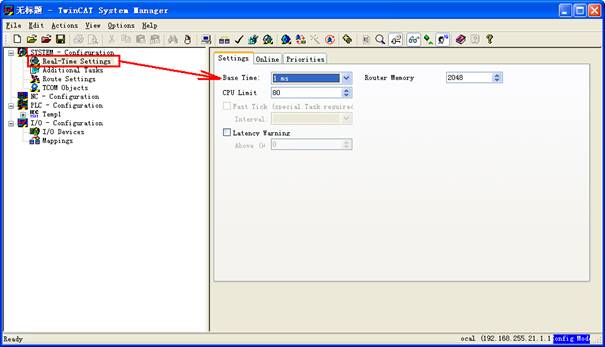

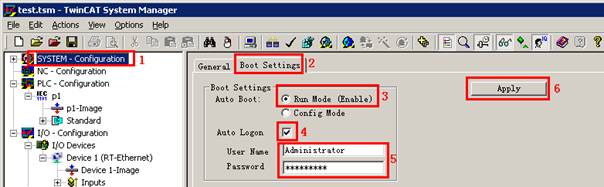

Setup Base Time.

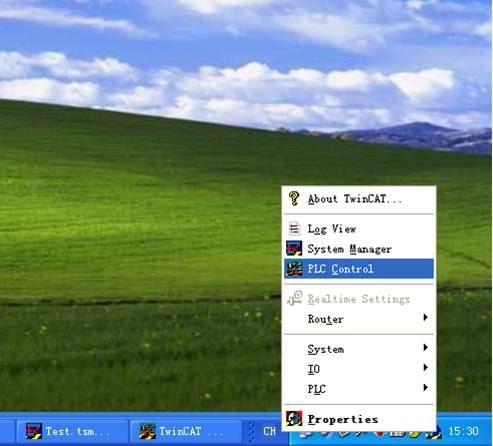

Enter to the PLC programming environment.

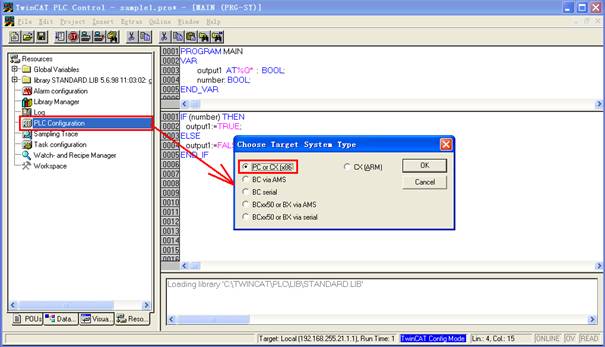

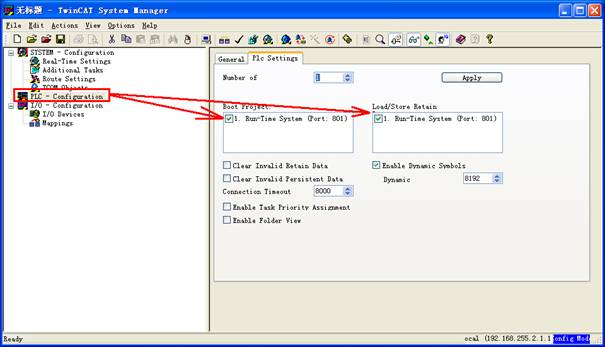

Double click PLC Configuration to choose target system type.

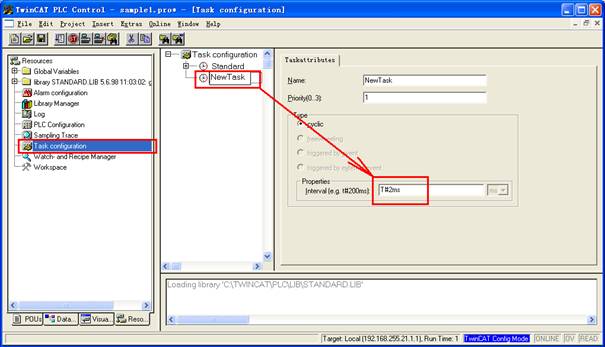

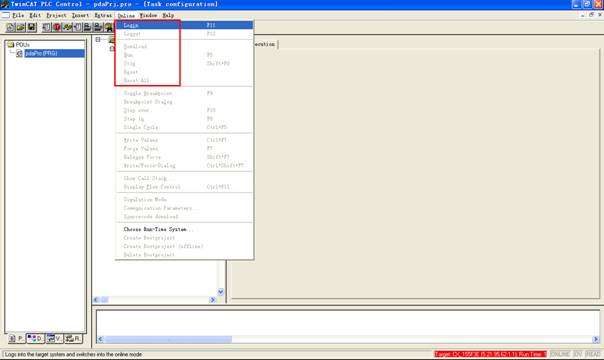

Double click Task configuration to create an 2ms task.

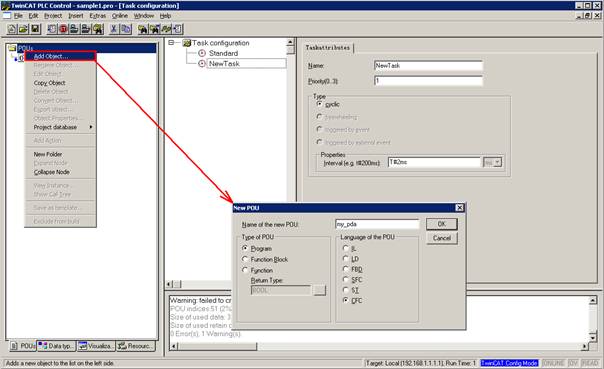

Right click to create a new program my_pda.

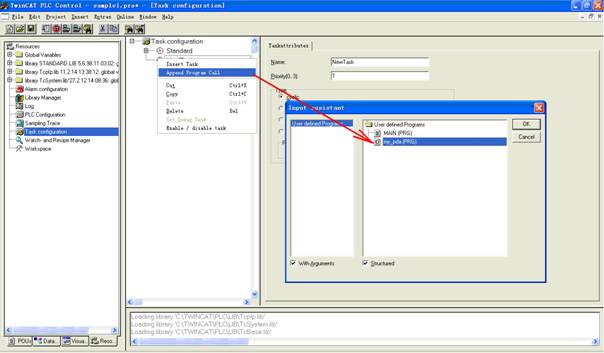

Add program my_pda to NewTask.

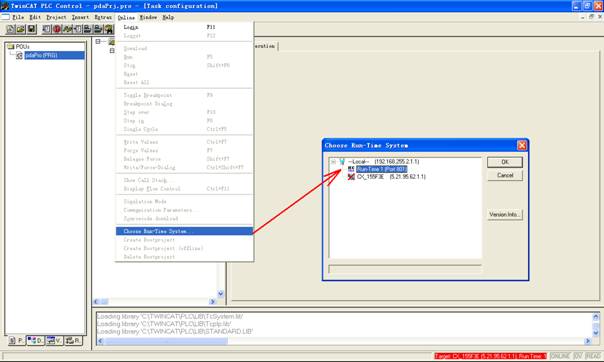

Choose run-time system.

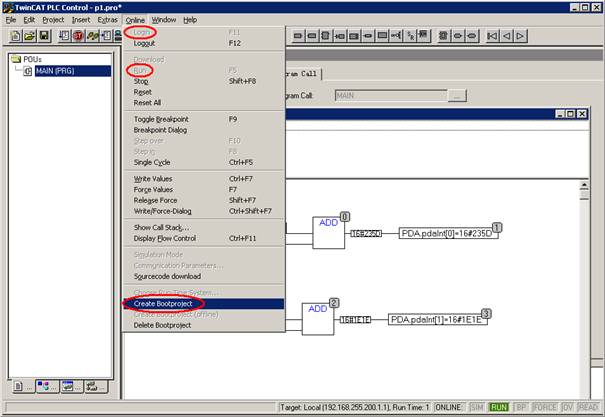

Login, download, reset, stop, run.

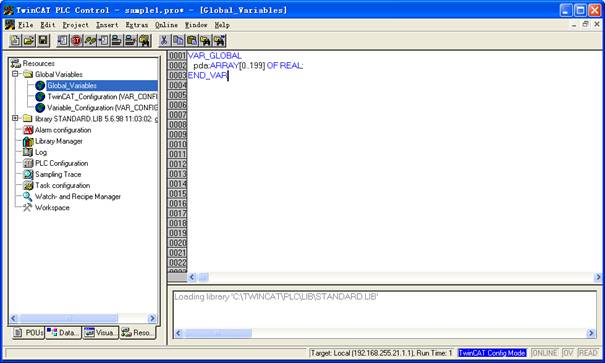

Declare global 200 real array for PDA.

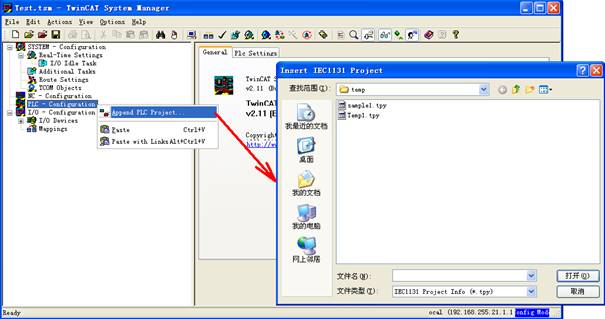

Open program my_pda Develop and save the project as temp1.pro, Compile and generate temp1.tpy Load compiled temp1.tpy in TwinCAT System Manager

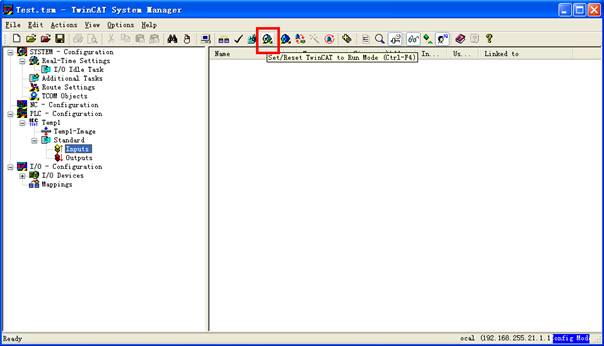

Activate configuration.

Switch to run mode.

Set PC as PLC Replace c:\TWinCAT\Driver\TCRtime.sys to avoid blue screen.

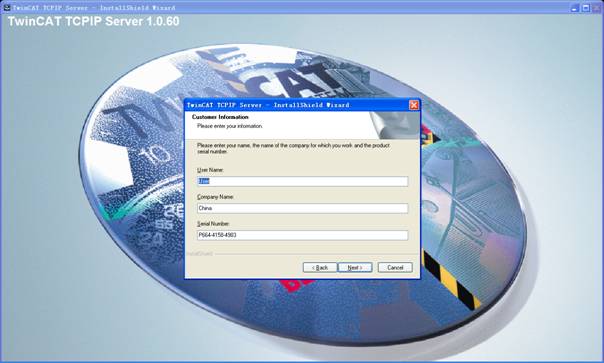

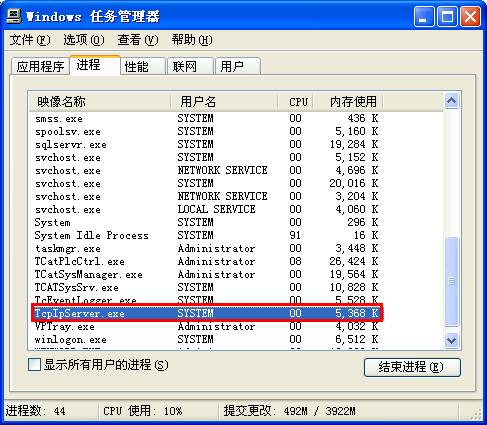

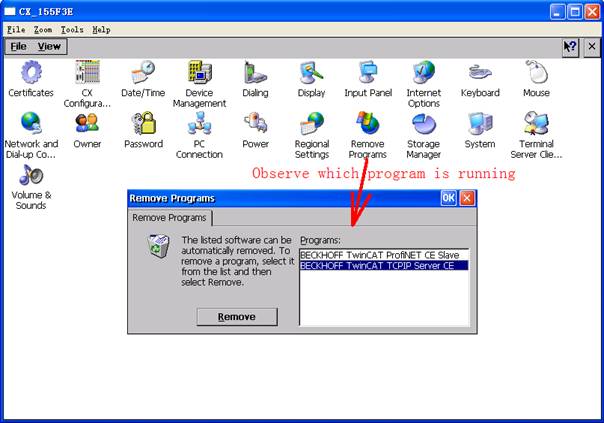

Ethernet protocol should be installed when WinXp work as PLC (Even if related files are copied to the corresponding position for the test version the Ethernet function can not run normally), The serial number is needed when you install. \TwinCAT TcpIp Server\Install\TcpIpServer.exe

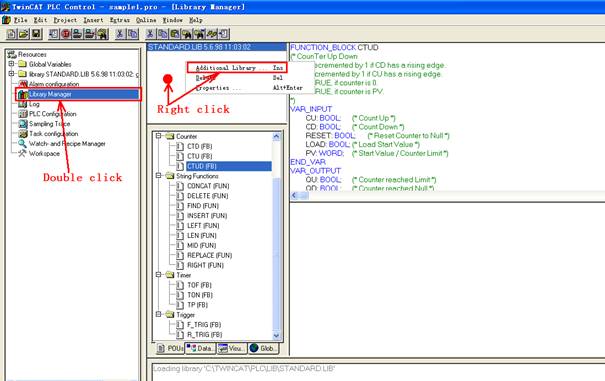

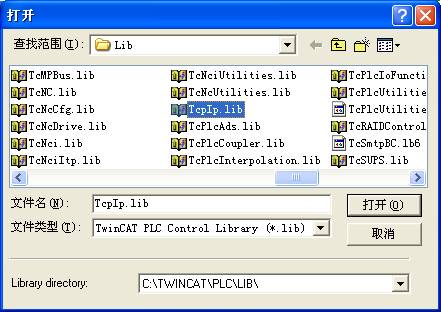

Copy ethernet library TcpIp.lib to \TwinCAT\Plc\Lib, add new library TcpIp.lib.

Run after project is loaded.

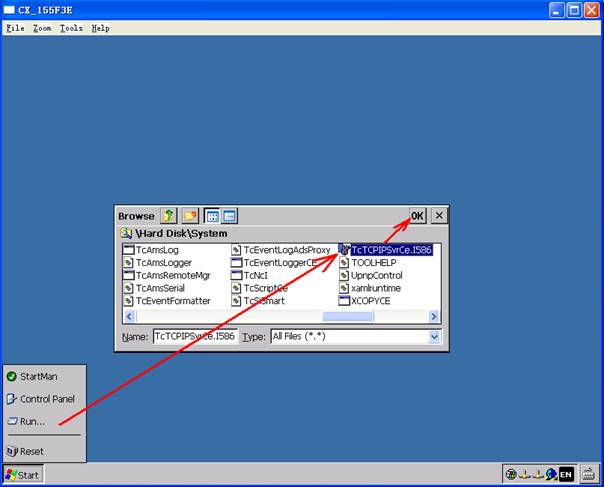

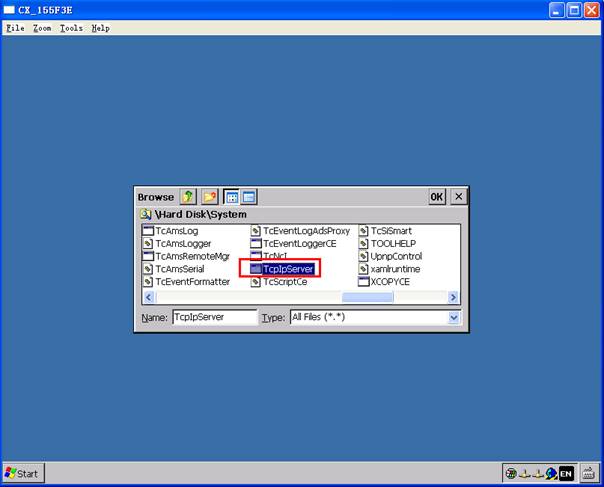

Copy TcTCPIPSvrCe.I586.CAB into the Flash card \Hard Disk\System\ with card reader for WinCE.

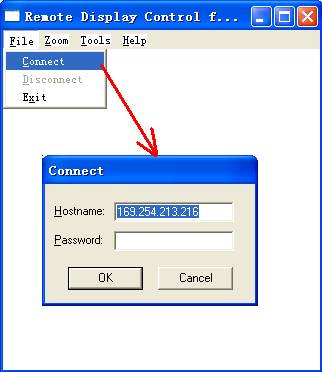

insert the card into PLC after copied and turn on. Start remote desktop "CERHOST.exe" of WinCE.

Run TcTCPIPSrvCe.I586.CAB, Extract to \Hard Disk\System\

The installation of ARM system is similar to above.

PDA server configuration for acquisition 300REAL/2ms is as follows. [1000,300CH,2.000ms,,25,Note,169.254.213.216] No,

Name,Adr/note,Unit,Len,Offset

,Gain

,Type,ALM, CH1=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 CH2=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 CH3=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 …… CH299=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 CH300=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 Set up startup project: Download the latest program from "TwinCAT PLC Control" and start "Create Bootproject" in the "Login" and "Run" states.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient