|

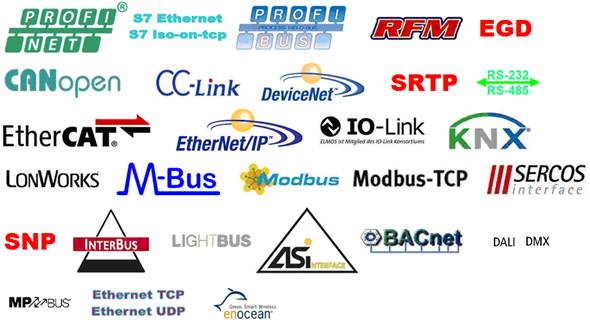

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||||||

|

Process Data

Acquisition – PDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||||||

|

|

|||||||||

|

6 DCC - Digital Coil Conversion and full process quality management |

|||||||||

|

20

Comprehensive data acquisition system for steelmaking plants |

|||||||||

|

21 A

large amount of S7 communication causes network instability |

|||||||||

|

23 |

|||||||||

|

11 HDP - High frequency density and speed Data Platform

construction |

24 |

||||||||

|

12 HDC - Hot rolled high-frequency high-density

Digital steel Coil |

|||||||||

|

26

Research Form for PDA System Config in the Steel Industry |

|||||||||

|

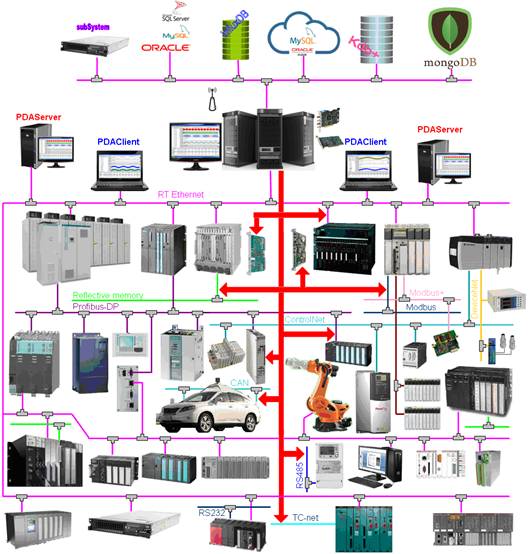

1 Background and performance

metrics

The PDA (Process Data

Acquisition) high-speed data acquisition and analysis system is an industrial

real-time high-speed data acquisition and analysis platform that integrates

data acquisition, compression, storage, and analysis. It has online and

offline analysis functions, and almost all of the underlying technologies of

control systems and communication protocols are involved. This is a major

technological weakness in KingWei Impress Moon Technology Co.,Ltd. uphold the principle of "cooperation, integrity, pragmatic, innovation" philosophy, Service to customers with valiant pursuit of high quality, high reliability of the product quality. It is a domestic successful example of research development innovation. After twenty years of development and innovation, mixed brand contacts reputation quality government and user support as a whole, the scale is moderate with production development and sales at home and abroad. become a supplier of industrial high-speed data acquisition and analysis system with support of relatively complete data source types, A whole set of technology standard has been constructed. In many years, our R & D team focus on communication protocol research and development, field bus analysis, high speed data acquisition, real-time data compression, mass data storage, online data analysis techniques, unlimited energy and enthusiasm have been poured into them, a series of PDA hardware and software products have successfully developed with sincere cooperation of related Companies after diligently exploring, The comprehensive performance indicator reaches the international leading level. Products design meets international standards, compatible with the domestic and foreign main electrical brand, to meet the industrial demand, has been widely used in metallurgical industry and the user's consistent praise is high. Don't stop pursuing the development trend of electronic control technology, strive to perfect technical and economic integration is the permanent mission of the KingWei. "To meet customer needs, create value for customers" is our eternal hope and action guide. 1.1

Data type

String: LSTRING[Length]: 2 + Length bytes are occupied, the first byte is max string length, the second byte is actual string length STRING[Length]: 1 + Length bytes are occupied, the first byte is actual string length CHAR[Length]: Length bytes are occupied Analog: SINT: signed char, int8, smallint INT: short, int16, shortint DINT: long, int32, longint, integer BYTE: USINT, unsigned char, uint8 WORD: UINT, uint16, unsigned int, DATE, S5TIME DWORD: UDINT, unsigned long, uint32, longword, cardinal, ulong, TIME,TIME_OF_DAY REAL: FLOAT, single DOUBLE: LREAL, DateTime Digital: BIT(BOOL, Boolean) Mixed arrangement 1.2

Sampling period

0.05ms ~ 10ms 1.3

Data compression

Realtime compression: focus on real-time and efficiency. Efficient compression: high compression ratio, pay attention to compression ratio. No compression: pay attention to openness. 1.4

Data acquisition mode

Industrial Ethernet, Profibus-DP, RFM and other network acquisition. Hardware interface module. PLC forwardly sends data, PDA server receives them. PDA server directly reads data from PLC. Data packet transmitted. 1.5

Data interface

Dos, Windows32/64, Linux32/64, Android, Mac OS, iOS and other platforms are supported. Fully open real time data interface Oracle or other database realtime interface Fully open historical data interface Fully compatible with third party data Quality management system and big data interface(Memory pointer + data file) HMI interface(Memory pointer + data file) Video synchronous data interface Plugins Data file generation completion interface ModbusTcp interface DDEServer interface 1.6

System structure and network topology

1.7

System functionality and performance

1.8

PLC, field bus and vendors

|

|||||||||

|

|

|||||||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||||||

Develop communication protocol, Customized

analysis function, Open data interface, XinChuang domestic obsession

PDAServer

PDAClient