|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – ikoPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

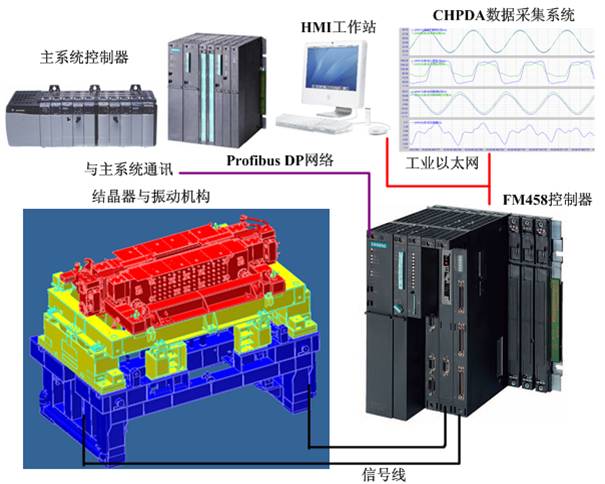

57

Continuous

Casting Hydraulic Vibration PDA System

Crystallizer is the core equipment of continuous casting machine. Compared with mechanical vibration, hydraulic vibration can effectively reduce the frictional resistance between the casting billet and the copper tube of the crystallizer, thereby improving the surface quality of the casting billet, increasing the pulling speed, and increasing the output; Adopting plate spring guidance, there is no mechanical wear, greatly reducing equipment maintenance workload and costs; Adopting high-precision prestressed leaf spring guidance, with small deviation in all directions; Online adjustable amplitude, frequency, and waveform to achieve sinusoidal and non sinusoidal vibration, suitable for the pouring process requirements of various steel grades. Debugging personnel can adjust various parameters based on the waveform to make feedback and settings follow as quickly as possible with minimal overshoot. Sometimes, blockage of servo valves due to unclean hydraulic system oil can be intuitively analyzed from the curve, which can quickly identify the cause. Generally, production workers can adjust the historical curve after discovering that the vibration has stopped, and quantitatively analyze whether it is signal interference, excessive friction, oil circuit blockage, or improper operation. Compared with the traditional eccentric cam crystallizer excitation system driven by DC or AC motors, the electro-hydraulic servo driven continuous casting crystallizer excitation system can achieve non sinusoidal vibration, significantly improve the lubrication of crystallizer protective slag, effectively reduce the friction between the billet and the crystallizer, thereby reducing billet vibration marks, improving billet quality and metal yield. The PDA system is used for real-time data acquisition and monitoring of the crystallizer vibration device, with a sampling period of 2ms. The collected data includes actual displacement, actual pressure, actual pulling speed, and actual servo valve status. It is a necessary tool for fault diagnosis and data analysis. 57.1 S7-400+FM458 scheme

This scheme is a classic control scheme for hydraulic vibration of crystallizers in the S7-400 era. Domestic design institutes and many companies engaged in steel industry control systems have developed mature vibration systems. FM458 is a high-performance CPU-PM6 control board based on SIMADYN D launched by SIEMENS. It has fast computing speed and uses a 128MHz, 64 bit RISC processor, which can provide high-performance computing power. The minimum control cycle of the task is 0.1ms. It integrates 8 digital inputs and extends the template EXM438-1. It can connect encoders, digital inputs, digital outputs, analog inputs, and analog outputs, trigger 8 interrupt tasks, and execute various high dynamic response applications such as torque, speed, position closed-loop control, and high dynamic response hydraulic drive. Therefore, many domestic users use it as a controller for hydraulic vibration of crystallizers. The S7-400 can collect data at high speed and fixed intervals (2ms) through Ethernet. FM458 synchronously transfers the data that needs to be collected to the CPU of S7-400 through the backplane bus, which packages it at high speed and sends it to the PDA server for real-time compression, storage, and analysis after the package is full. When there are not many collection points, but a fast collection cycle is required, this scheme is adopted. The sampling cycle can be up to 2ms, and the PDA data source type is 0. Pay attention to filling in the CPU slot number. The network port of the CPU built-in or independent Ethernet card can be used. It is recommended to use Siemens upgraded network cards such as 6GK7 443-1EX20-0XE0, which have much higher performance than 6GK7 443-1EX11-0XE0.

57.2 TDC scheme

TDC is widely used in hydraulic vibration of crystallizers. SIMATIC TDC (Process and Transmission Control) is a digital automation system with extremely high computing power that can handle very large programs. It provides a comprehensive library with approximately 300 functional blocks for quick configuration. (1) Advantages SIMATIC TDC provides the highest performance motion control and closed-loop control technology capabilities. SIMATIC TDC stands out for its efficient and synchronous multiprocessor system. (2) Application SIMATIC TDC is particularly suitable for use in factory configurations in metallurgy, steel rolling mills, and power distribution fields.

57.3 Beckhoff scheme

The Beckhoff controller is widely used in hydraulic vibration and electro-hydraulic servo direct drive vibration of crystallizers. The controller operating system is WinCE and adopts Realtime Ethernet communication protocol.

57.4 Simotion D scheme

Simotion D is a high-end motion control system with high response performance from Siemens, widely used in hydraulic vibration of crystallizers. Siemens' Simotion D motion controller based on drives integrates motion control, process, and PLC functions directly into the drives. User benefits: high machine cycle frequency, repeatable product quality, significant cost savings, and lower space requirements inside the control cabinet. Simotion D is an ideal combination of controller and driver, compact, flexible, economical, and highly responsive: through Simotion D, PLC functions, process functions, and motion control functions are directly integrated into the control module of the SINAMICS S120 drive system. Simotion D application areas: (1) High end machines For complex multi axis machines that require extremely short cycle times and achieve high-quality product quality through deterministic and repeatable machine characteristics, it is an ideal solution. (2) Compact machine When complex applications need to be implemented in a very small space, Simotion D is recommended. Due to the combination of controllers and drivers in one system, Simotion D occupies very little space inside the control cabinet. (3) Modular machine In modular scenarios, Simotion D can serve as a supplement to Simotion P or Simotion C systems. The systems are connected through PROFINET that supports IRT. (4) Distributed automation solution Simotion D is suitable for multi axis machines where each machine module is controlled by a Simotion controller, and the modules exchange process values with each other in synchronous mode (distributed synchronization). (5) Adverse environmental conditions The optimized Simotion D SIPLUS model is suitable for use under harsh operating conditions, such as in environments containing harmful gases.

57.5 S7-1500 scheme

Since Siemens launched the S7-1500, this series of hydraulic vibration controllers for crystallizers has gradually been adopted, requiring the use of S7-1517 or higher controllers.

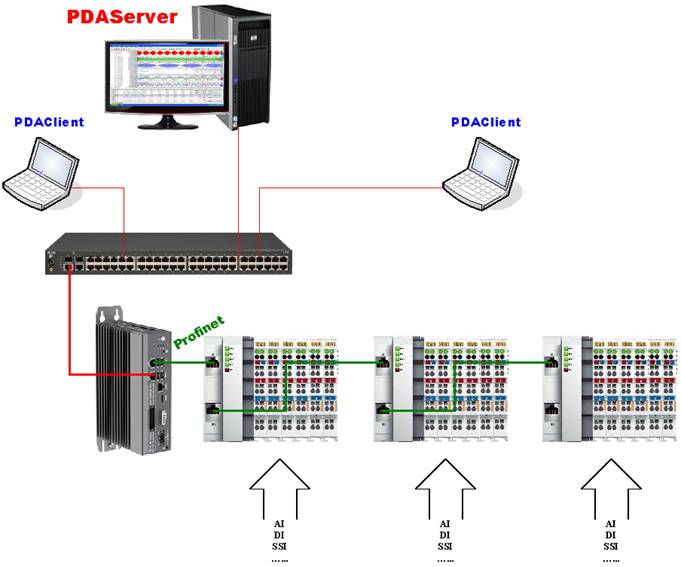

57.6 Hardwired solution

When the controller network performance is poor and cannot meet the millisecond level data transmission, this solution is adopted. Similar solutions are also available in Siemens AC main drive, which are currently being phased out as a last resort high-speed data acquisition solution. The IO module is selected as a high-speed type with an AD conversion accuracy of 16 bits.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient