|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – ikoPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

13

S7-1500/1200

13.1

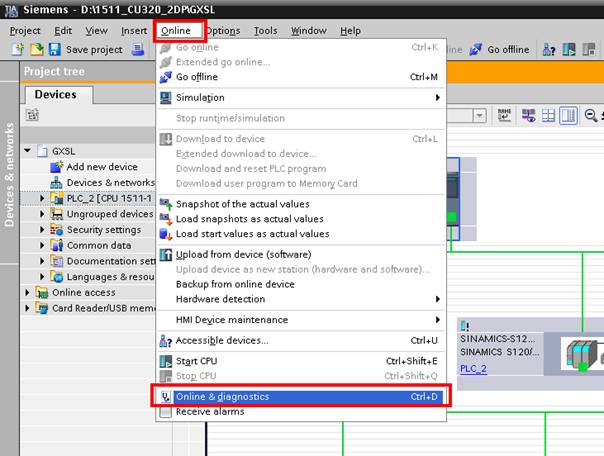

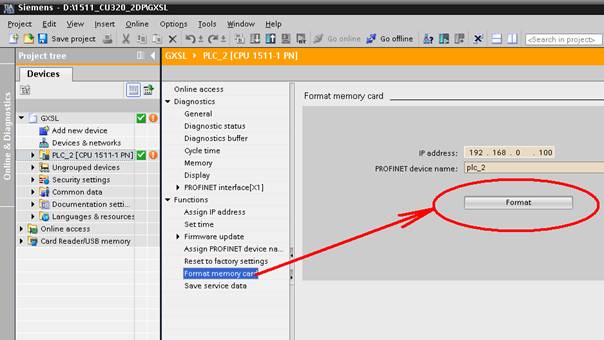

Format memory card

There must be a memory card for 1500 running, S7-1200 does not need, and new memory cards or other cards removed from different CPUs may need to be formatted before they can be used. Press the RUN film button or switch toggle to RUN position to allow CPU to run.

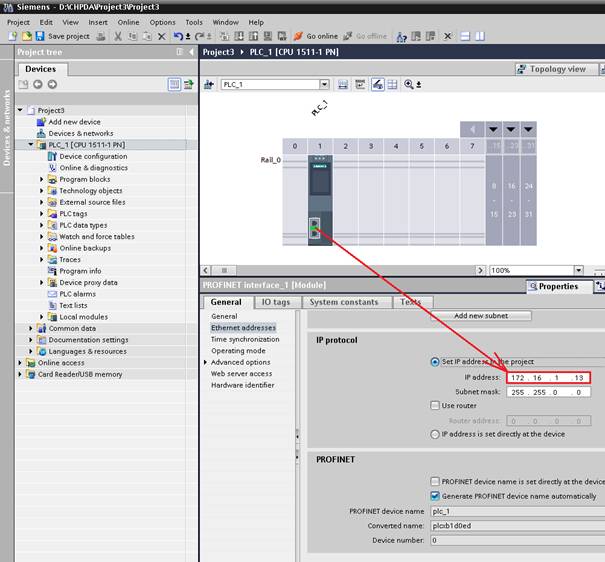

13.2 UDP schemeCreate a project, add device 1500CPU.

Set up IP address.

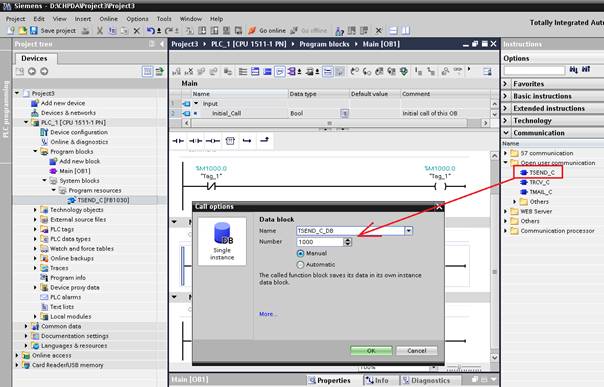

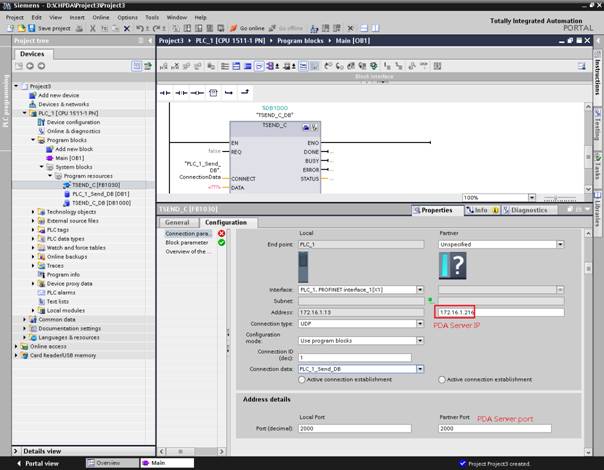

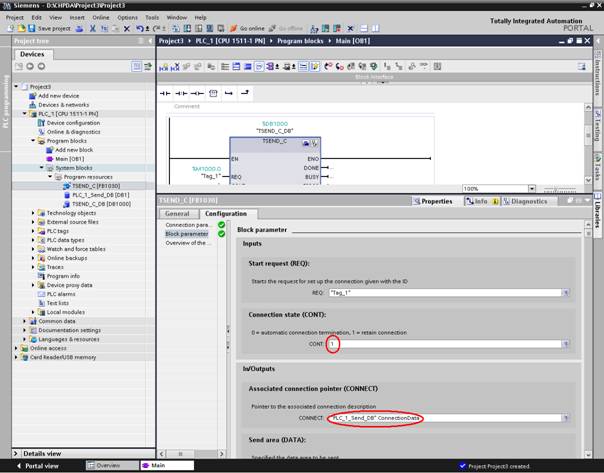

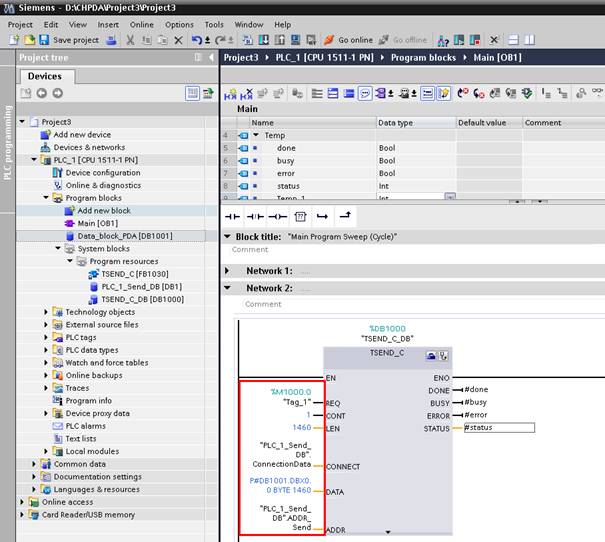

Insert function block "TSEND_C" in OB1.

The TSEND_C property is set according to the following figures.

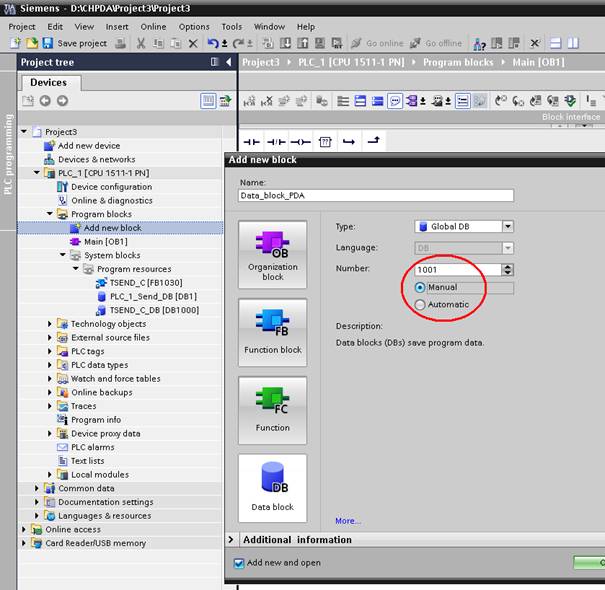

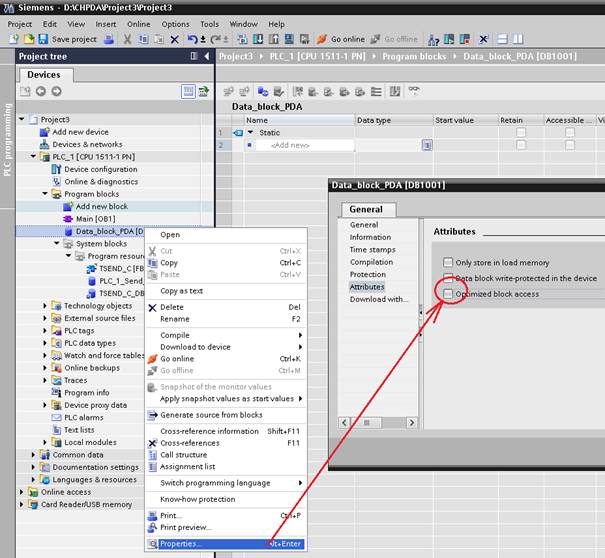

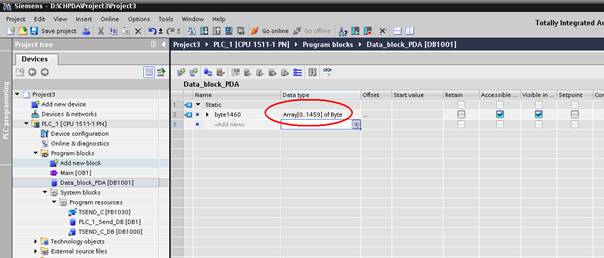

Add a data block to store the data to be sent to PDA.

The optimized attribute of the data block should be canceled, the optimized data block cannot be addressed by a pointer.

Up to 1460 bytes are collected once.

Data_block_PDA->property->general->Data type: array[0..1459] of byte, the sending function block start sending at rising edge, so that data is sent per two OB1 scan cycles, Store data to the data block before sending.

Config.csv of PDA is below: [2000,1460CH,10.000ms,172.16.1.13,25S,S7-1500,172.16.1.216] No,

Name,Adr/note,Unit,Len,Offset

,Gain

,Type,ALM, CH1=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH2=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH3=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH4=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH5=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH6=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH7=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH8=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , …… CH1459=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CH1460=, ,

, ,4 ,0.000000,1.000000,BYTE,0 ,0.000,0.000,0.000,0.000,0 , CPU1518 is much faster than CPU below 1516 and may guarantee normal data transfer, otherwise the data transmission cycle will drift when the program is too large. The example of sending data block assignment scl program in PLC is as follows. "Data_block_1".r[0] :=

"Data_block_1".r[0] + 0.001; "Data_block_1".r[1] :=

SIN("Data_block_1".r[0] ); "Data_block_1".r[2] :=

COS("Data_block_1".r[0]); "Data_block_1".bool16[0] := TRUE; "Data_block_1".bool16[1] := FALSE; 13.3

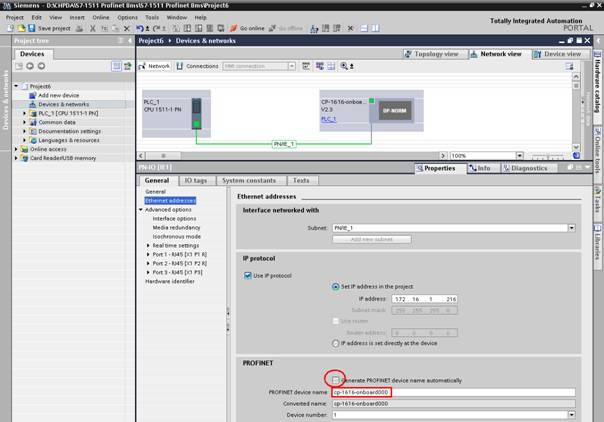

Profinet scheme

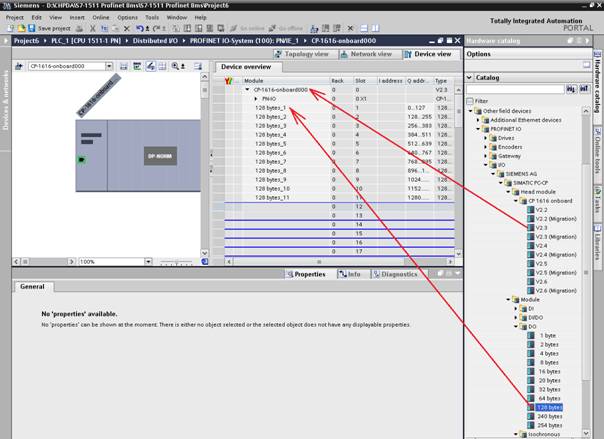

See section 4.7 for Config.csv of PDA. Save collected data to a DB and move it to Profinet Q address together. Steps of PLC config is below. Many device drivers need to be installed separately in TIA Portal 15.0, CP-1616 is one of them, Insert a Profinet slave drop of CP-1616.

Config requiring data, it must be multiple of 128bytes, the most bytes are 1408.

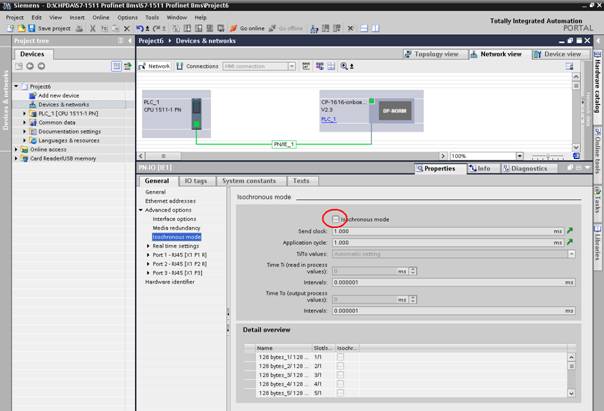

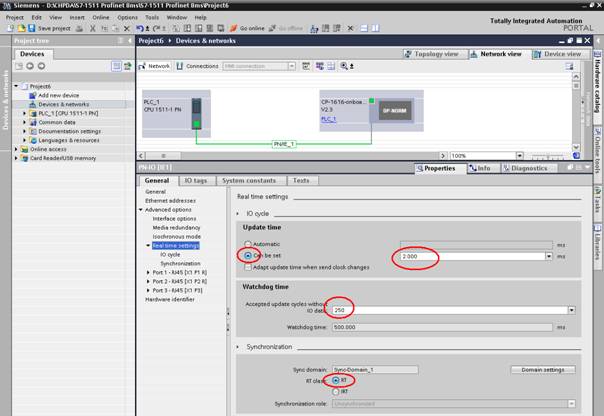

Set isochronous mode.

Set IO cycle and watchdog time.

13.4

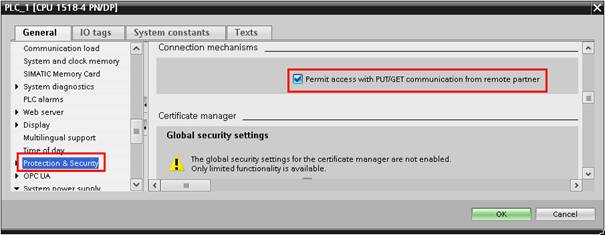

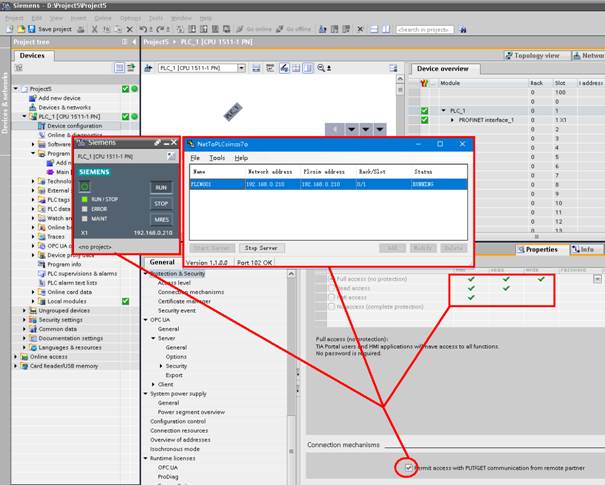

Read directly PLC memory address

The optimized attribute of the collected data block should be canceled. See section 4.8 for other. "Full access(no protection) " and "Permit access with PUT/GET communication from remote partner(PLC,HMI,OPC,...)" should be selected for PLC configuration.

13.5

S7-1500 simulator

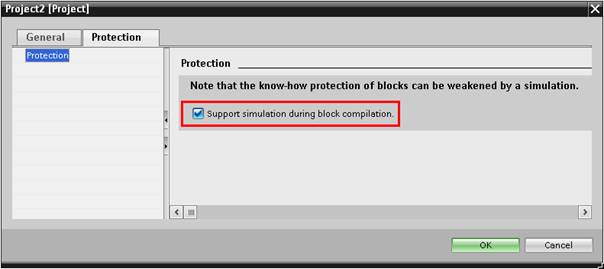

Select the "Support simulation during block compilation" option in the PLC project properties protection, click on the project, and right-click on the properties.

Select "Permit access with PUT/GET communication from remote partner" in the PLC property "Protection & Security".

NetToPLCsim can simulate S7 communication of S7-1500, but cannot simulate Opc Ua of S7-1500.

S7-PLCSIM Advanced is a high-performance simulator launched by SIEMENS, equivalent to S7-PLCSIM+NetToPLCsim. Its notable feature is that it can simulate communication, including Opc Ua, in addition to general PLC logic control programs. Before installation, WinPcap is installed, and after installation, an additional virtual network card called Siemens PLCSIM Virtual Ethernet Adapter will be added to the computer.

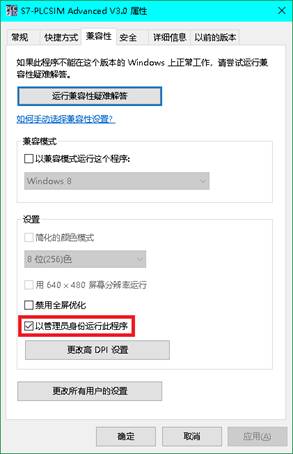

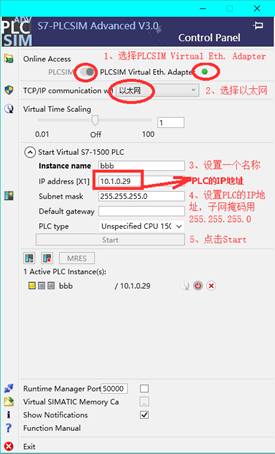

The use of this software can be executed and determined according to the steps below. It is important to remember the following points to pay attention to, otherwise a small issue may waste half a day's time. Method 1: When S7-PLCSIM Advanced and Portal are installed on two computers respectively, both the physical network card and virtual network card in the above figure are set to automatically obtain IP addresses and DNS server addresses. S7-PLCSIM Advanced software needs to run with administrator privileges: You can directly right-click each time to run with administrator privileges. If you want to run it permanently, you can click on the icon, right-click on properties, and in compatibility, check the option to run this program as an administrator. After running the S7-PLCSIM

Advanced software, follow the settings shown in the figure below to ping

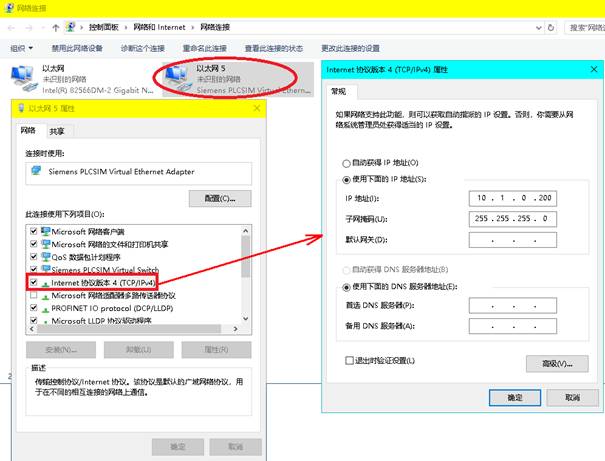

Method 2: When installing S7-PLCSIM Advanced and Portal on the same computer, follow the steps below to set them up. (1) Set the physical network card to automatically obtain an IP address, and set the virtual network card to the same network segment IP address as the PLC.

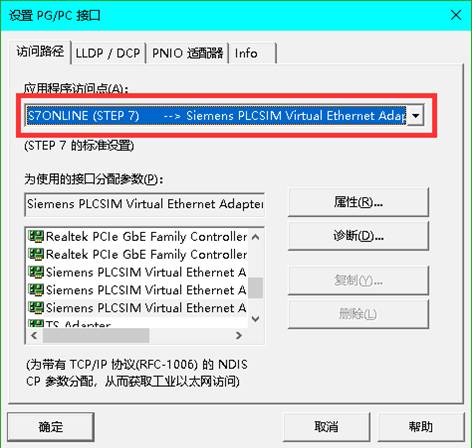

If the local network card is set to a fixed IP address, there will be a "incompatible device detected" message when downloading. (2) Set PG/PC interface: Open the PG/PC interface through the control panel and set the application access point as shown in the following figure:

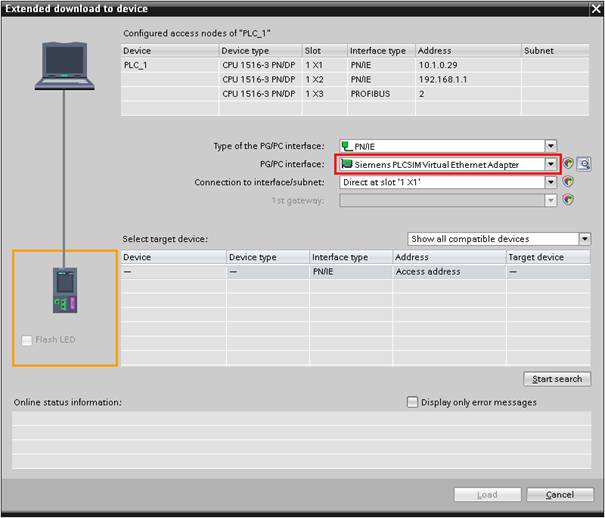

(3) Run S7-PLCSIM Advanced as an administrator and set the same method. (4) When downloading PLC programs, set the PG/PC interface to Siemens PLCSIM Virtual Ethernet Adapter.

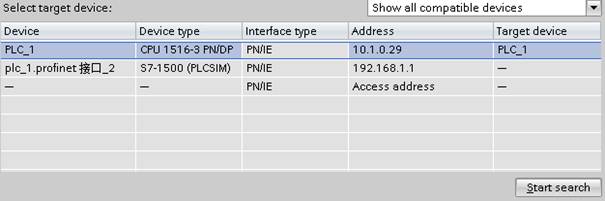

(5) Select to display all compatible devices, click start search, and once found, click download.

13.6 Modify

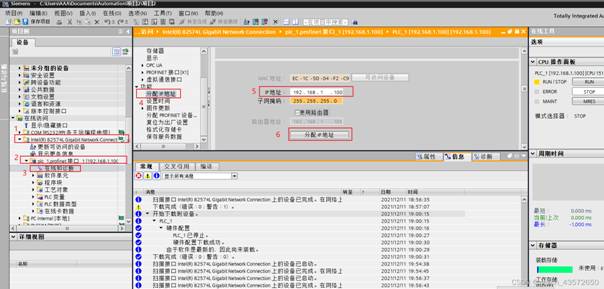

the PLC IP address

Let the PLC in a stopped state and set it according to the following diagram.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient