|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – PDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

32

EtherCAT

EtherCAT (Control Automation

Technology) is an open architecture fieldbus system based on Ethernet,

initially developed by Beckhoff Automation GmbH in EtherCAT advocates for "Ethernet control automation technology", which is an open source, high-performance system. EtherCAT is an IEC specification (IEC/PAS 62407). There are currently multiple Ethernet solutions used to provide real-time functionality: for example, by prohibiting CSMA/CD access processes through higher-level protocol layers and replacing them with time slices or polling processes, other solutions use dedicated switches and use precise time control to allocate Ethernet data packets, although these solutions can quickly and accurately transmit data packets to the connected Ethernet nodes, However, the utilization rate of bandwidth is very low, especially for typical automation devices, because even for very small amounts of data, a complete Ethernet frame must be sent, and the time required to redirect to the output or driver controller, as well as read input data, mainly depends on the execution method, usually requiring the use of a sub bus, especially in modular I/O systems, which are similar to the Beckhoff K-bus, By synchronizing the sub bus system to accelerate transmission speed, such synchronization will not avoid causing delays in communication bus transmission. By adopting EtherCAT technology, Beckhoff breaks through the system limitations of other Ethernet solutions: it no longer needs to receive Ethernet packets at each connection point as before, then decode and copy them into process data. As frames pass through each device (including the underlying terminal device), the EtherCAT slave controller reads data that is crucial to that device. Similarly, Input data can be inserted into the message when it passes. When a frame is passed (delayed by only a few bits), the slave station will recognize the relevant command and process it. This process is implemented through hardware in the slave station controller, and is therefore independent of the real-time running system or processor performance of the protocol stack software. The last EtherCAT slave station in the network segment will return the fully processed message, which will be returned as a response message from the first slave station to the master station. From the perspective of Ethernet, the EtherCAT bus segment is just a large Ethernet device that can receive and send Ethernet frames. However, this "device" does not include a single Ethernet controller with downstream microprocessors, but only a large number of EtherCAT slave stations. Like any other Ethernet, EtherCAT does not require a switch to establish communication, resulting in a pure EtherCAT system. Each device in the system ensures the use of a complete Ethernet protocol, even for each I/O terminal, without the need for a sub bus. Simply convert the transmission medium of the coupler from twisted pair (100baseTX) to an E-bus to meet the requirements of the electronic terminal strip. The E-bus signal type (LVDS) inside the terminal strip is not specialized, and it can also be used for 10 Gigabit Ethernet at the end of the terminal strip, The physical bus characteristics are converted back to the 100baseTX standard. A standard Ethernet MAC or inexpensive standard network card (NIC) is sufficient as hardware in the controller, while DMA (direct memory access) is used to transfer data to the PC, which means that network access has no impact on CPU performance. The same principle is applied in the Beckhoff multi-port card, which bundles up to 4 Ethernet channels in a PCI slot. Protocol processing is entirely carried out in hardware, and protocol ASICs can be flexibly configured. The EtherCAT protocol is optimized for process data, which is directly transmitted to Ethernet frames or compressed into UDP/IP data packets. The UDP protocol is used when EtherCAT network segments in other subnets are addressed by routers. Ethernet frames may contain several EtherCAT messages, each dedicated to a specific storage area that can be mapped with logical processes up to 4GB in size. Since the data link is independent of the physical order of EtherCAT terminals, EtherCAT terminals can be arbitrarily addressed, and slave stations can broadcast, multicast, and communicate with each other. This protocol can also handle typically non cyclic parameter communication, and the structure and meaning of parameters are set through CANopen device profiles, which are used for various device categories and applications. EtherCAT also supports slave profiles that comply with the IEC61491 standard. This industry regulation is named after SERCOS and is widely recognized in the field of motion control applications worldwide. In addition to data exchange that conforms to the principle of master/slave station, EtherCAT is also very suitable for communication between controllers (master/master station), freely addressable process data network variables, and various parameterization, diagnosis, programming, and remote control services, which can meet many requirements. The data interface used for master/slave station and master/master station communication is the same. FMMU: Message processing is entirely done in hardware. EtherCAT has reached a new level of network performance, with a refresh cycle of only 30 for 1000 distributed I/O data μ s. This includes terminal cycle time, which can exchange up to 1486 bytes of process data through an Ethernet frame, which is almost equivalent to 12000 digital I/Os, and the transmission of this data volume only takes 300 bytes μ S. Communication with 100 servo axes only requires 100 μ s. During this period, setting values and control data can be provided to all axes, and their actual positions and states can be reported. Distributed clock technology ensures that the synchronization time deviation between these axes is less than 1 microsecond. By utilizing the excellent performance of EtherCAT technology, control methods that cannot be achieved with traditional fieldbus systems can be achieved. In this way, ultra high speed control loops can also be formed through the bus. Functions that previously required local dedicated hardware support can now be mapped in software. The vast bandwidth resources enable parallel transmission of state data with any data. EtherCAT technology matches communication technology with modern high-performance industrial PCs, The bus system is no longer the bottleneck of control concepts, and the data transmission of distributed I/O exceeds the performance that can only be achieved by local I/O interfaces. This network performance advantage is more evident in small controllers with relatively moderate computing power. EtherCAT's high-speed loop can be completed between two control loops, so the controller always has the latest available input data and the output addressing delay is minimized. On the basis of not enhancing its own computing power, the response behavior of the controller is significantly improved. The principle of EtherCAT

technology is scalable, not limited to EtherCAT can replace PCI, and with the accelerated development of miniaturization of PC components, the size of industrial PCs mainly depends on the number of slots required. The utilization of high-speed Ethernet bandwidth and EtherCAT communication hardware (EtherCAT slave controller) data bandwidth has opened up new application possibilities: interfaces typically located in IPC are transferred to intelligent interface terminals in EtherCAT systems. In addition to decentralized I/O, axes, and control units, complex systems such as fieldbus master stations, high-speed serial interfaces, gateways, and other communication interfaces can be addressed through an Ethernet port on a PC. Even other Ethernet devices without protocol variants can be connected through distributed switch terminals. Industrial PC hosts are becoming smaller and cheaper, and a single Ethernet interface is sufficient to handle all communication tasks. Replacing PCI fieldbus devices (PROFIBUS, CANopen, DeviceNet, AS-i, etc.) with Ethernet for integration through distributed fieldbus master terminals saves PCI slots in the PC. It can achieve data collection with an effective sampling period of 0.1ms, and the data source type is 5. STRING data type is not supported. Please use CHAR instead, and FC1100 or FC1121 support is required. The configuration method is similar to the previous section. Beckhoff et al. are representatives.

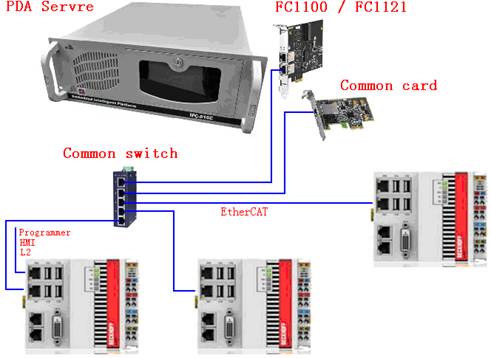

Propose to establish an independent EtherCAT network for high-speed data acquisition, typical network diagram is as follows:

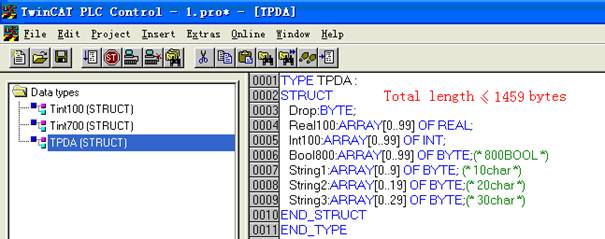

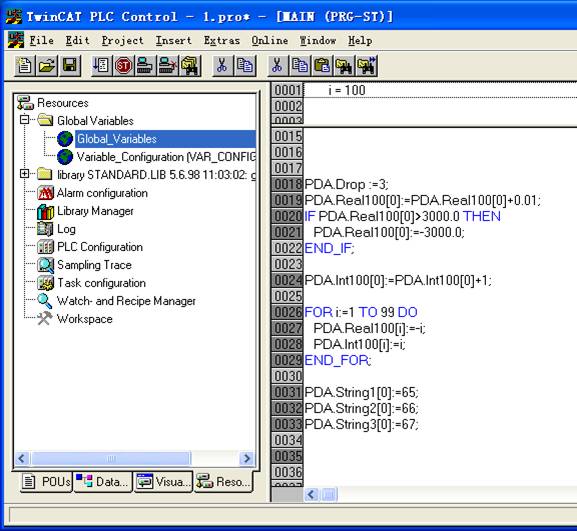

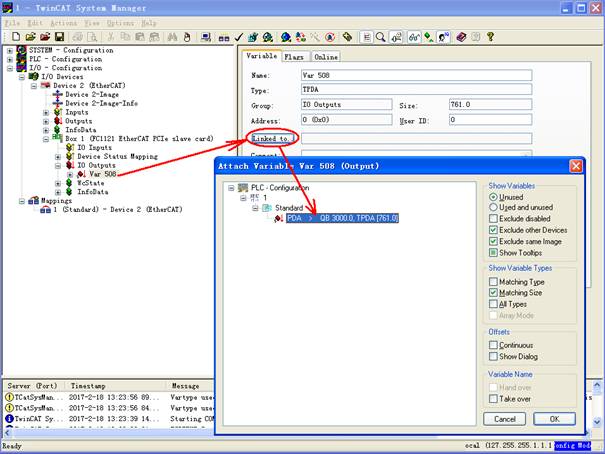

Define a structure TPDA according to signals to be collected in the PLC program, note that the first byte is for the PLC master station number, and it corresponds to the connection identification number in Config.csv.

The program sends values to the TPDA instance, such as PDA AT%QW1000:TPDA;

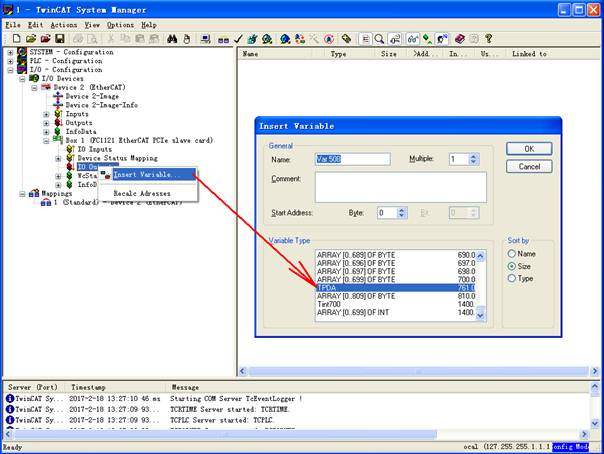

Insert a variable connected to the PDA in the configuration software.

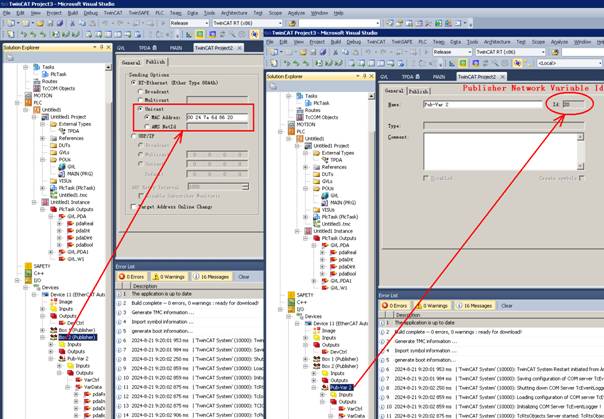

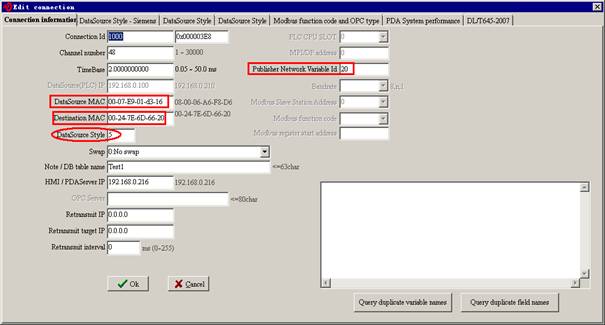

Method 2: No dedicated EtherCAT slave network card is required. Establish a connection and select EtherCAT Automation Protocol [Network Variables] under the EtherCAT communication protocol. EtherCAT transmits data according to MAC address, as shown in the figure below. The PDA data source type is 5, and for others, refer to section 4.34. Example programs and PDA configurations can be found on EtherCAT_TwinCAT3.zip.

The configuration in PDA is shown in the following figure.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient