|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data Acquisition – CHPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

63

MQTT

63.1

MQTT Communication Methods and Topics

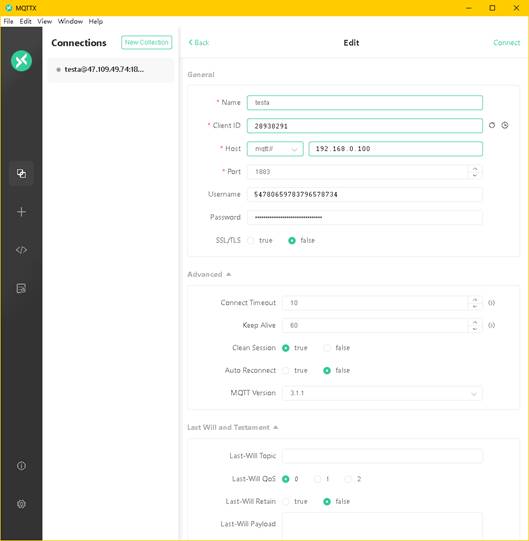

By using a front-end processor and signal field configuration method, cloud services can be provided to dozens of PLCs within the local area network simultaneously, isolating the internal and external networks, reducing the burden on PLCs, enhancing the flexibility of MQTT services, and saving information costs. The MQTT service program runs in a loop once every 1 second, but due to the involvement of millisecond level alarms, all variables require a certain duration of millisecond level data caching. Supports SSL/TLS encryption. 63.1.1 Server and TopicA certain project: Broker IP address: 192.168.0.100 Broker port: 1883 Client ID:28938291, The project number is 28938291 Username:54780659783796578734 Password: trkmoij696859u98ut5toikr3

Topic: $sys/28938291/dp front-end processor pushes real-time PLC data to the outside world. $sys/28938291/cmd Send commands to the front-end processor or PLC through mobile apps or other means. $sys/28938291/alarm The front-end processor pushes PLC alarm information to the outside. $sys/28938291/event The front-end processor pushes PLC operation records and other event information to the outside world. $sys/28938291/cfg The front-end processor pushes naming configuration information to the outside, including signal name, comment, type, unit, etc., with a delimiter of Tab. It pushes comment information according to the request, and does not push without a request. It is not supported to retrieve configuration information for connecting all points at once. It must be retrieved by point and multiple points can be retrieved at once. Based on the topic and its msgId, it is possible to determine which connection, data content, and flow to access. 63.1.2 Push real-time data messages$sys/28938291/dp Push real-time data for points 20, 23, and 32 with connection identification number 1000. {"msgId": "1000","msgKey": "data","sourceTime": 1753619526193,"data": {"20": "1.267","23": "100.76","32": "89"}} 63.1.3 Write data to PLCSend the following message via $sys/28938291/cmd and write 1 to the point 1 with connection identification number 1000. {"msgId": "1000","msgKey": "data","sourceTime": 1753619526193,"data": {"1": "1"}} Send the following message via $sys/28938291/cmd and write 1 to the point 2 with connection identification number 1000. {"msgId": "1000","msgKey": "data","sourceTime": 1753619526193,"data": {"2": "1"}} 63.1.4 Force reading of connection point configuration informationSend the following message via $sys/28938291/cmd to retrieve the configuration information for points 1, 2, and 3 with connection identification number 1000. {"msgId": "1000","msgKey": "cfg","sourceTime": 1753619526193,"data": {"1": "","2": "","3": ""}} Return message such as: $sys/28938291/dp {"msgId": "1000","msgKey": "cfg","sourceTime": 1753619526193,"data": {"1": "current","2": "voltage","3": "speed"}} 63.1.5 Force reading of real-time values of connection pointsSend the following message via $sys/28938291/cmd to forcibly read the real-time values of points 1, 2, and 3 with connection identification number 1000. {"msgId": "1000","msgKey": "data","sourceTime": 1753619526193,"data": {"1": "Refresh","2": " Refresh ","3": " Refresh "}} 63.1.6 Force reading of real-time values for all connected pointsSend the following message via $sys/28938291/cmd to forcibly read the real-time values of all points with connection identification number 1000. {"msgId": "1000","msgKey": "data","sourceTime": 1753619526193,"data": {"All": "Refresh"}} 63.2

MQTT message format

The message format is determined by specific projects, and the message format for a certain project is as follows: { "msgId": "xxxxxxxxxx", "msgKey": "data", "sourceTime": 112213232323, "data": { "field1 serial number ": "12.33", "field2 serial number ": "23", "field3 serial number ": "True" } } There are no line breaks in the actual message, and spaces are either cancelled or only one space character is retained, which is case sensitive, UTF-8. 63.2.1 message IdMsgId is the message ID number, which is the identification number for the connection. 63.2.2 AlarmSet by ALM field in Config.csv. bit0: Conventional upper upper, upper, lower, and lower lower limit alarms, setting by HH, HI, LO, and LL in Config.csv. bit1: Trend alarm, alarm for changes within a certain period of time bit2: Millisecond level alarm with upper upper, upper, lower, and lower lower limits bit3: Millisecond level change rate alarm, time interval set by Tail(s) field in Config.csv, less than 1.0 second bit4: bit5: bit6: bit7: 63.2.3 Operation logSet the log through the Opr field in the Config.csv file. bit0: Desktop or box bit1: HMI bit2: Event, value change is pushed bit3: bit4: bit5: bit6: bit7: 63.2.4 Message keywordsmsgKey is a message keyword, and "data" and "cfg" are valid keywords. 63.2.5 Telegram timesourceTime is the message

time, Uint64, The millisecond value of time is in 63.2.6 Field DescriptionMulti layer nesting is not supported. 63.2.7 When pushing real-time values"Field1 Number" refers to the field number, such as 1, 2, 3, 4, 5, etc. Please refer to the Config.csv or request push for the corresponding field name. The value of the field is after the "Field1 number". Which variables can be set to

push outward, set by the GFlag field bit The periodic signal will push the changed field value outward once every 1-60 seconds, and the time value is set by the Head(s) field in the Config.csv, with a default value of 3 seconds. Real time triggering and pushing of alarm and other information. 63.2.8 When issuing commands to the front-end processor"Field1 Number" refers to the field number, such as 1, 2, 3, 4, 5, etc. After "Field1 Number", the value to be written to the PLC for this field. When the field value is "Refresh", request to force the external push of this field value once. Request to force all field values of the connected device to be pushed externally once when "Field1 ID"="All" and field value="Refresh". 63.3

Communication of MQTT front-end machine writing data to PLC

63.3.1 ModbusTcpWhen using the Modbus TCP communication protocol, a continuous memory block of %Mxxx and %MWxxx is established in the PLC for the front-end machine to access, and the data block is sent to the PDA in UDP mode for defining signal names, addresses, types, units, etc. When the PLC receives a button type Bool signal, it is reset by the PLC. 63.3.2 Standard Socket TcpWhen using the standard Socket Tcp method, the PLC defines the memory block that requires variables and sends the data block to the PDA via UDP. When the PLC receives a button type Bool signal, it is reset by the PLC. 63.3.3 Other methodsOPC, OPC UA, Private communication protocol for PLCs from various manufacturers. |

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient