|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

|||

|

Process Data

Acquisition – ikoPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

||||

|

|

||||

|

6 DCC - Digital Coil Conversion and full process quality management |

||||

|

20

Comprehensive data acquisition system for steelmaking plants |

||||

|

21 A

large amount of S7 communication causes network instability |

||||

|

23 |

||||

|

11 HDP - High frequency density and speed Data Platform

construction |

24 |

|||

|

12 HDC - Hot rolled high-frequency high-density

Digital steel Coil |

||||

|

26

Research Form for PDA System Configuration in the Steel Industry |

||||

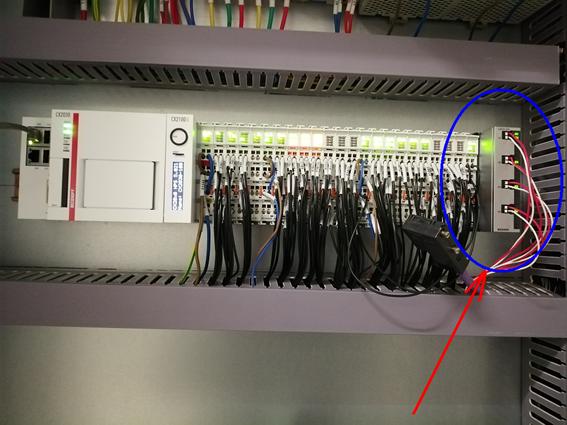

8 DSO - Device

diagnostic Synchronous Oversampling system

8.1

Implementing 50us data acquisition through PLC

DSO - Device diagnostic Synchronous Oversampling system is based on PDA system. PDA system supports data acquisition of 50 kHz and 0.02 ms sampling period, the full historical data are stored, the real-time FFT calculation and curve analysis are supported, flexible and continuous time slice may be selected, the special AD converter board and special storage system may be used, the standard PLC system is also used to complete signal access and quickly realize system deployment. The over sampling AI module of PLC system can realize the sampling rate of 16KHz, 20kHz, etc., which can meet the access of acceleration sensor, speed sensor, displacement sensor, etc. in the equipment diagnosis system. At the same time, the process data such as speed, current, pressure, flow, temperature and other conventional acquisition cycle signals can also be accurately and synchronously collected, avoiding the complicated offline alignment work in the later stage. The system is simple and transparent, online and offline data can be directly connected to the diagnostic analysis system, and the calculation results can be obtained immediately, supporting 2 million spectral lines.

Beckhoff ELM series of measurement technology ELM3xxx Siemens ET200 SP HS AI 6ES7531-7NF10-0AB0 AI 8xU/I HS

Figure 8.1 Equipment Diagnosis Data Acquisition System Based on PLC

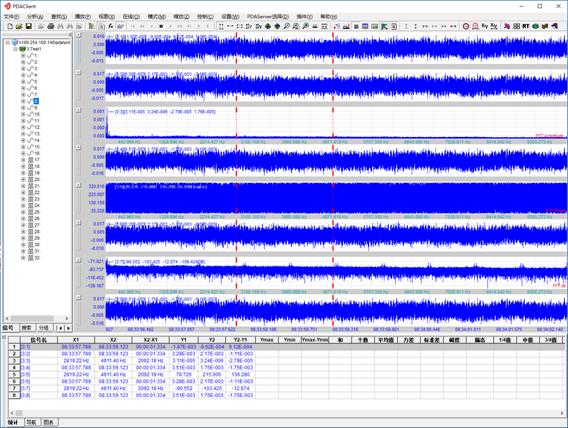

Figure 8.2 Beckhoff PLC oversampling data acquisition Real-time FFT calculation and curve analysis.

Figure 8.3 real-time FFT calculation and curve analysis 8.2

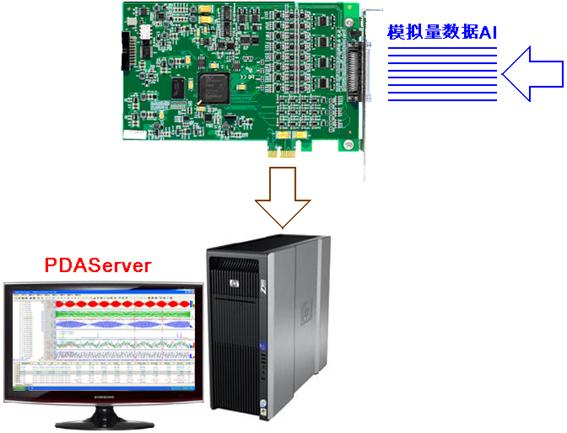

Implementing 50us data acquisition through PCIe card

It can synchronously collect 16 channel signals with a resolution of 16 bits. The data acquisition card is inserted into the PCIe slot of the computer, and the PDAServer collects real-time data from 16 channels every 50us. The real-time data is used for real-time analysis and efficiently compressed into. dat data files for offline analysis.

Figure 8.4 16 bit 16 channel data acquisition card 8.3

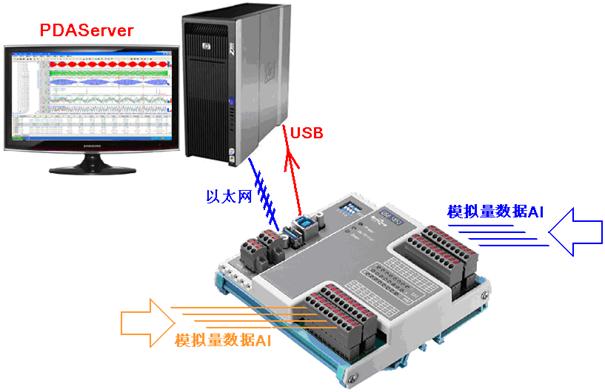

Realize 50us data acquisition through USB or Ethernet interface

board

It can synchronously collect signals from 18 channels with a resolution of 16 bits. The CPU in the interface board performs high-speed synchronous acquisition of data from the 18 channels and stores it in the memory buffer. Every millisecond, the data in the buffer is sent to the PDA computer via a USB cable or Ethernet. The PDA Server parses the data from each channel according to the data storage convention in the buffer for real-time analysis and compresses it throughout the process into an offline .dat data file. The number of channels can be reduced or expanded, and the sampling period can also be adjusted.

Figure 8.5 16 bit 18-channel data

acquisition board |

|

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|

Develop communication protocol, Customized

analysis function, Open data interface, XinChuang domestic obsession

PDAServer

PDAClient