|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

|||

|

Process Data

Acquisition – ikoPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

||||

|

|

||||

|

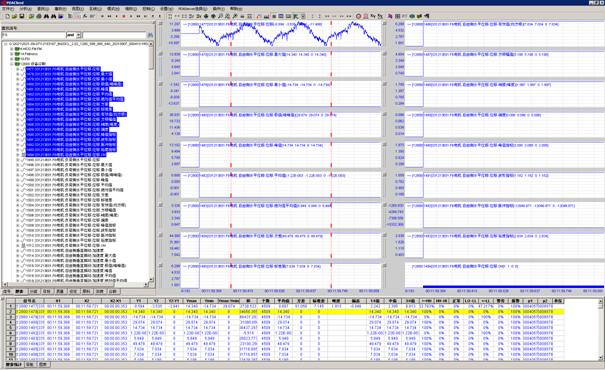

6 DCC - Digital Coil Conversion and full process quality management |

||||

|

20

Comprehensive data acquisition system for steelmaking plants |

||||

|

21 A

large amount of S7 communication causes network instability |

||||

|

23 |

||||

|

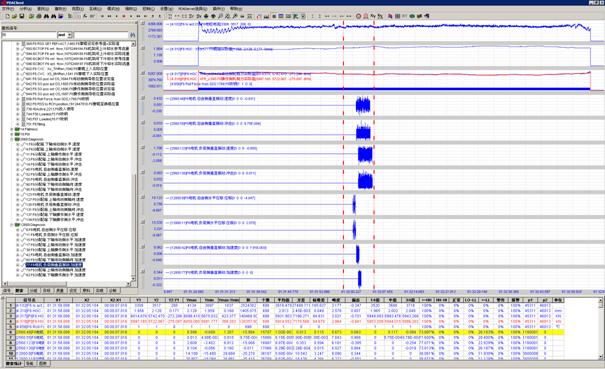

11 HDP - High frequency density and speed Data Platform

construction |

24 |

|||

|

12

HDC - Hot rolled high-frequency high-density Digital steel Coil |

||||

|

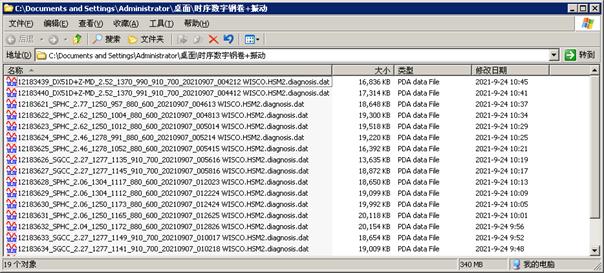

26

Research Form for PDA System Configuration in the Steel Industry |

||||

12 HDC - Hot

rolled high-frequency high-density Digital steel Coil

Hot rolling is divided into three zones: roughing, finishing, and coiling, Rolling mill belongs to large-scale equipment, It is necessary to correlate process data for equipment diagnosis.

Figure 12.1 Hot rolling and finishing mill unit 12.1

Equipment digital steel coil - high frequency - ms

Focus on physical quantities that can reflect changes in device performance, such as device response, following performance, rate of change, amount of change, etc., with a sampling period of 10ms.

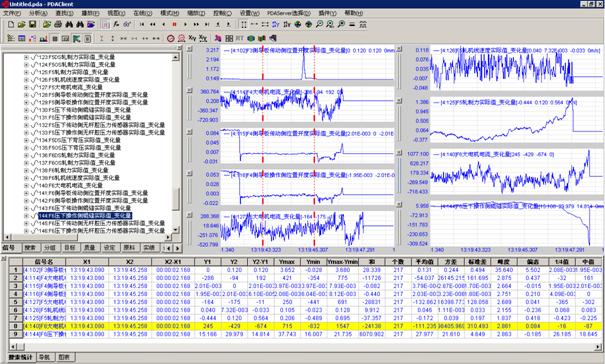

Figure 12.2 Curve of Equipment Digital Steel Coil Record 12.2 Equipment

Diagnosis Digital Steel Coils - ultra high frequency - µs

The time-series digital steel coil integrated with equipment diagnostic data is the equipment diagnostic digital steel coil. The displacement and acceleration sampling frequency of a certain project is 12.8KHz, and the speed and impact sampling frequency is 2.56KHz. Each sampling length is 8192 points, and sampling is conducted once per minute. According to the principle of time alignment, it is associated with the steel coil number (the equipment diagnostic system is not associated with the steel coil number but has time synchronization with the main rolling line), and the sampling value after 10 seconds of biting steel is taken as the effective value. Based on the long-term trend of vibration characteristic values of time-series digital steel coil equipment, the equipment status is judged, and the conclusion of equipment health status is drawn. This provides direction for specialized analysis and reduces workload. The specific fault points and content are analyzed by specialized tools to obtain more detailed diagnostic reports. The equipment diagnosis digital steel coil integrates the ultra-high frequency original vibration waveforms of each steel head, middle, and tail. With new feature value calculation methods and adjustment of calculation parameters, it is easy to recalculate the historical steel coil quickly. This is based on several fixed feature values in the database that cannot be compared. If the equipment diagnosis system has conducted full process data collection, it will associate the data of the head, middle, and tail based on the bite signal and the steel coil number.

|

|

|

|

|

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|

Develop communication protocol, Customized

analysis function, Open data interface, XinChuang domestic obsession

PDAServer

PDAClient