|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

|||

|

Process Data

Acquisition – PLC-PDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

||||

|

|

||||

|

6 DCC - Digital Coil Conversion and full process quality management |

||||

|

20

Comprehensive data acquisition system for steelmaking plants |

||||

|

21 A

large amount of S7 communication causes network instability |

||||

|

23 |

||||

|

11 HDP - High frequency density and speed Data Platform

construction |

24 |

|||

|

12 HDC - Hot rolled high-frequency high-density

Digital steel Coil |

||||

|

26

Research Form for PDA System Configuration in the Steel Industry |

||||

10 RCM - Roller Current

Monitoring system

The Roller Current Monitoring system monitors the status of the roller bed, which can timely avoid surface scratches on the strip and identify other conditions of the roller bed. Ultimately, it achieves roller bed status prediction, proactive maintenance, improves equipment online rate, reduces fault time, and improves product surface quality. The hot rolling laminar flow roller bed is located between the finishing mill and the coiler, and its main function is to deliver the finished strip steel to the coiler. At the same time, when the strip steel is transported on the laminar flow roller bed, cooling water will continue to spray above the roller bed to cool the strip steel. The total length of the laminar roller bed is generally over a hundred meters, with hundreds of rollers. Hundreds of rollers are controlled by several controllers, each controlling multiple motors to control the operation of a group of rollers, with approximately 10 to 30 rollers in a group. Due to the high water vapor and temperature in the working environment of the laminar flow roller table, it is easy for the roller table to overheat and lose lubricating grease. Water vapor often seeps into the motor, causing faults such as motor grounding, low motor insulation, and motor jamming. This can further cause scratches on the strip steel, seriously affecting product quality. For motor monitoring, it is usually arranged to manually monitor the current of the motor on the display interface with the naked eye. When abnormal changes in current are found, a manual alarm is given. Due to the presence of multiple sets of roller tracks with multiple motors, the amount of motor data is enormous, and some abnormal current changes are difficult to detect with the naked eye, making it difficult for manual detection of motor faults in a timely manner. The layout of a rough rolling roller table is shown in the following figure:

Figure 10.1 Hot Continuous Rolling Rough Rolling Roller Track The layout of a certain layer of cold roller table is shown in the following figure:

Figure 10.2 Cold Roller Table for Hot Continuous Rolling Layer The installation diagram of current transformer is as follows:

Figure 10.3 Layout of Motor Current Transformer 10.1

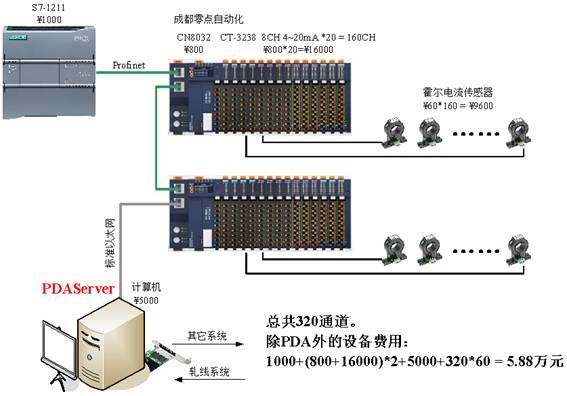

PLC+Remote IO Solution

The PLC adopts Siemens S7-1200 series, and the remote IO adopts well-known domestic brands. The refresh time of each current in this scheme can not exceed 10ms.

Figure 10.4 Schematic diagram of current monitoring system based on PLC 10.2

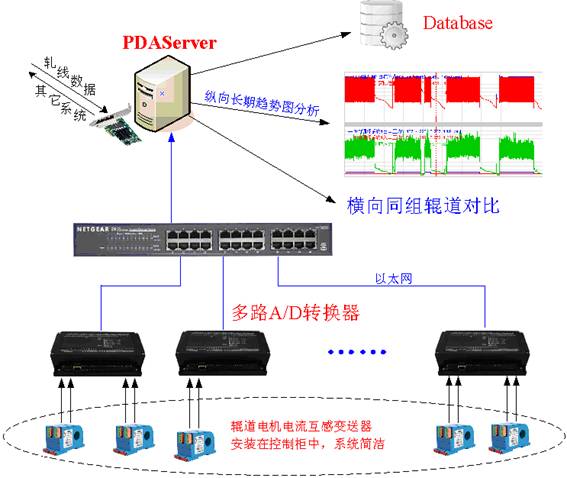

AD Conversion + ModbusTcp Integrated Interface Module Solution

Shijiazhuang Kunhang KHAQ-E-32AI, each module can accept 32 channels of 4~20mA signals, ¥1,500 per unit, with a total of 10 units required. Total cost: 1500*10 + 60*320 (current sensors) + 2000 (switches) + 5000 (computer) = 41,200 yuan. Disadvantage: In this solution, the A/D conversion is shared among multiple channels, which may result in a refresh time exceeding 50ms per channel. The block diagram of the current monitoring system is as follows:

Figure 10.5 Schematic Diagram of a Current Monitoring System Based on an Integrated Module Considering both cost and performance, Solution 1 is recommended. |

|

|

|

|

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|

Develop communication protocol, Customized

analysis function, Open data interface, XinChuang domestic obsession

PDAServer

PDAClient